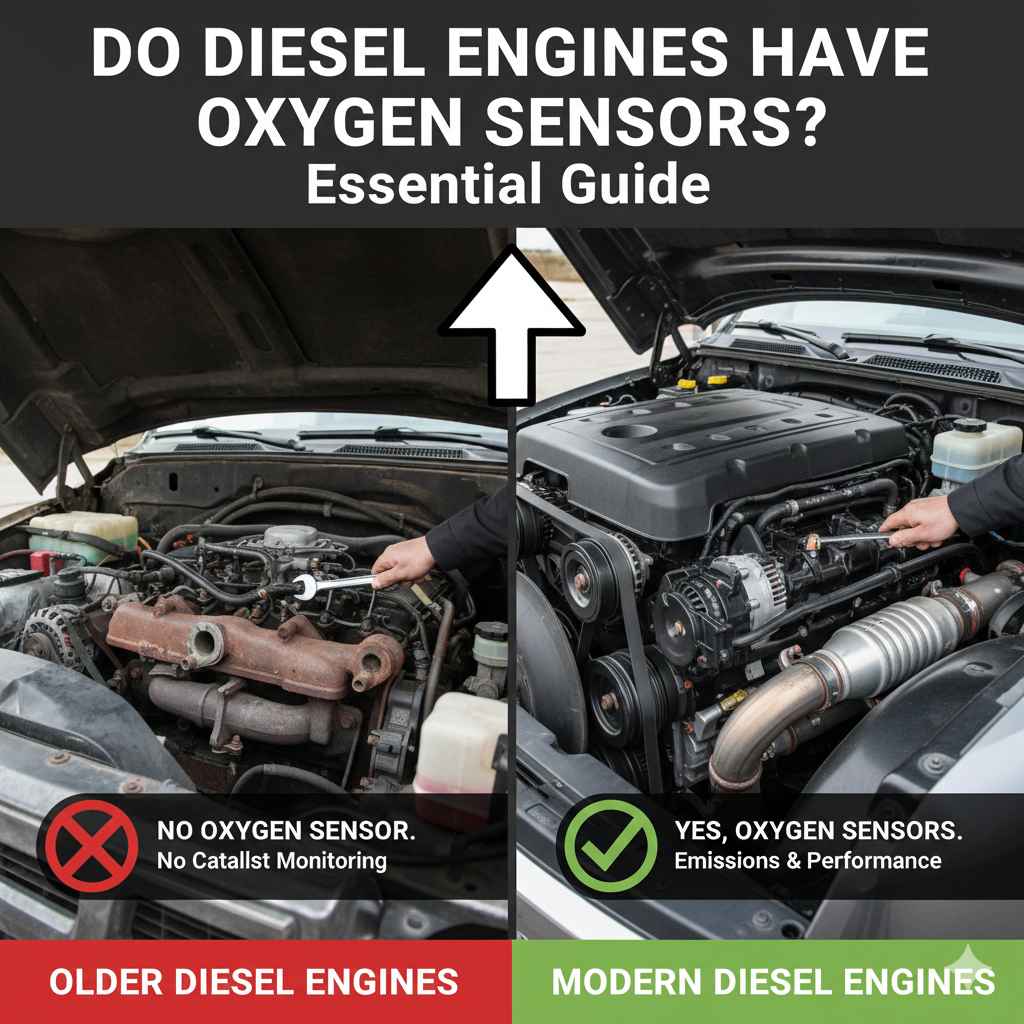

Do Diesel Engines Have Oxygen Sensors? Essential Guide

Yes, modern diesel engines absolutely have oxygen sensors (O2 sensors), but they often use a different type, known as a Wideband Air-Fuel Ratio (AFR) sensor, specifically to manage emissions controls like the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) systems.

It’s a common question that causes confusion among car owners: do diesel engines use the same oxygen sensors as gasoline cars? If your “Check Engine” light is on, or you’re just curious about how your diesel truck works, understanding these sensors is key to keeping it running smoothly. Diesel systems are different, but they rely heavily on sensors to meet strict modern emissions standards. You might be surprised just how important these little parts are for performance and efficiency. Don’t worry; we are going to clear up all the technical terms and give you a simple roadmap to understanding diesel oxygen sensors, no matter your experience level. By the end of this guide, you’ll know exactly what they do and how to look out for trouble.

Why Diesel Engines Need Sensors: The Emissions Challenge

Gasoline engines burn fuel to create power. Diesel engines do things differently; they use intense compression to ignite the fuel. Because of this, diesel exhaust contains different pollutants, mainly Nitrogen Oxides ($text{NO}_text{x}$) and particulate matter (soot). To clean this up, modern diesel engines are packed with complex after-treatment systems. Every one of those systems needs to talk to the main computer (the ECU) to work correctly. That’s where the sensors come in.

The Basics: What is an Oxygen Sensor (O2 Sensor)?

In the simplest terms, an oxygen sensor measures how much oxygen is in the exhaust gas coming out of the engine.

Gasoline Cars (Stoichiometric Ratio): Gasoline engines use a very specific air-to-fuel ratio (about 14.7 parts air to 1 part fuel). The O2 sensor tells the computer if the mix is rich (too much fuel) or lean (too much air) so it can constantly adjust the fuel injector pulse width.

Diesel engines (Lean Burn): Diesel engines almost always run very lean—meaning there is always excess air. They don’t need the exact same control as a gasoline engine. This is why the standard “Narrowband” O2 sensor isn’t their main tool for fuel control.

Diesel Engines and Their Specific Sensors: AFR vs. O2

So, the answer to “Do diesel engines have oxygen sensors?” is yes, but they often use a more advanced version.

The Wideband Air-Fuel Ratio (AFR) Sensor

Most modern, clean-burning diesel engines use a Wideband AFR sensor instead of, or in addition to, a traditional narrowband O2 sensor. This sensor is much more accurate across a wider range of exhaust gases.

How the AFR Sensor Works

Think of the AFR sensor as an advanced chemist monitoring the exhaust. It doesn’t just say “too much oxygen” or “too little oxygen.” It can measure the exact ratio, even when there’s a lot of extra air present (which is normal for a diesel).

1. Measures Exhaust: It sits in the exhaust stream, usually before the catalytic converter.

2. Sends Detailed Data: It sends a detailed voltage or current signal back to the Engine Control Unit (ECU).

3. Controls Emissions: The ECU uses this precise data to fine-tune two major areas:

Regeneration Cycles: If your Diesel Particulate Filter (DPF) is getting clogged, the ECU needs to run a “regeneration” (burning off the soot). The AFR sensor helps ensure the exhaust temperature and air mixture are perfect for this cleaning process.

DEF System Management: In Selective Catalytic Reduction (SCR) systems that use Diesel Exhaust Fluid (DEF), the sensor helps ensure enough exhaust gas is present for the $text{NO}_text{x}$ reduction to work optimally.

Where Are These Sensors Located in a Diesel Exhaust System?

The placement of these sensors is critical to what they measure. Diesel exhausts often have multiple sensors monitoring different stages of emission cleanup.

| Sensor Location | Typical Sensor Type | Primary Function |

|---|---|---|

| Upstream (Before the DPF/DOC) | AFR Sensor (Wideband) | Monitors engine combustion efficiency and helps initiate DPF regeneration. |

| Downstream (After the DPF) | $text{NO}_text{x}$ Sensor (Specific to SCR) | Measures the efficiency of $text{NO}_text{x}$ reduction after the SCR catalyst. |

| Exhaust Pipe (Older Diesels) | Narrowband O2 Sensor | Less common; might monitor basic backpressure or simple fuel trim adjustments. |

If you are working on a diesel from around 2007 or newer in the US, you are almost certainly dealing with AFR sensors and dedicated $text{NO}_text{x}$ sensors.

The Critical Role of $text{NO}_text{x}$ Sensors in Modern Diesels

If the AFR sensor handles the air/fuel mix and DPF health, what about the other big pollutant, $text{NO}_text{x}$? This is where a specialized sensor comes into play that is often confused with a standard O2 sensor: the $text{NO}_text{x}$ Sensor.

Nitrogen Oxides ($text{NO}_text{x}$) are formed when high heat and pressure cause nitrogen and oxygen in the air to combine. Since diesels run hot and under compression, $text{NO}_text{x}$ is a big problem.

What $text{NO}_text{x}$ Sensors Do

Diesel engines use SCR systems to destroy $text{NO}_text{x}$. Diesel Exhaust Fluid (DEF, or urea) is injected into the exhaust. Inside the SCR catalyst, the DEF turns $text{NO}_text{x}$ into harmless nitrogen and water.

The $text{NO}_text{x}$ sensor’s job is crucial: it confirms that the SCR system is actually working as intended.

- Upstream $text{NO}_text{x}$ Sensor: Measures the amount of $text{NO}_text{x}$ entering the SCR catalyst.

- Downstream $text{NO}_text{x}$ Sensor: Measures the amount of $text{NO}_text{x}$ leaving the SCR catalyst.

The ECU compares the reading from the upstream sensor to the downstream sensor. If the difference is small (meaning a lot of $text{NO}_text{x}$ was removed), the system is efficient! If the difference is large (meaning little reduction occurred), the ECU flags a problem, often turning on the “Service Required” light or initiating a “Limp Mode.” This compliance is strictly enforced by agencies like the Environmental Protection Agency (EPA) in the United States (Learn about EPA standards for diesel emissions).

Signs That Your Diesel Sensor Might Be Failing

Whether it’s a dedicated O2 sensor, an AFR sensor, or a $text{NO}_text{x}$ sensor, any failure will impact performance or cause expensive emissions system shutdowns. Since these sensors live in a very hot, dirty environment, they don’t last forever.

Here are the most common warning signs that one of your exhaust gas sensors is going bad:

- Check Engine Light (CEL) or Emissions Light: This is the most obvious sign. The code will rarely just say “Bad O2 Sensor” on a diesel; it usually points to an emissions system reading error, like “Low Efficiency SCR Catalyst” or “AFR Sensor Circuit Malfunction.”

- Reduced Fuel Economy: If the computer can’t accurately read the exhaust, it defaults to a safe, fuel-heavy map, which wastes diesel.

- DPF Regeneration Issues: The soot filter might fail to clean itself because the AFR sensor isn’t providing the right temperature data, leading to eventual clogging.

- Poor Performance or Engine Derating: If the $text{NO}_text{x}$ or AFR sensor fails completely, the ECU may intentionally limit engine power to reduce stress on the emissions components.

- Noticeable Smell/Smoke: In extreme cases where the mixture is uncontrolled, you might notice black smoke (soot) or a strange sulfur smell.

Troubleshooting: What You Will Need (Basic Tools)

Fixing or checking these sensors is often a straightforward process once you have the right tools. Always disconnect the battery before working on electrical components.

Essential Toolkit for Sensor Checks:

OBD-II Scanner (Must be capable of reading live diesel data, not just generic codes).

Socket and wrench set (usually metric).

Oxygen Sensor Socket (a deep socket with a slot for the wire harness).

Torque Wrench (crucial for proper installation).

* Anti-seize compound (for the sensor threads).

Safety Note: Before replacing any sensor, always check the wiring harness leading to it. Melted or damaged wires are often the real culprit, not the sensor itself!

Step-by-Step: Replacing a Diesel Exhaust Sensor Safely

If your diagnostics point straight to a faulty sensor (either the AFR sender or a $text{NO}_text{x}$ sensor), replacement is a doable DIY job. This general guide applies to most non-EGR-restricted diesel passenger and light-duty trucks.

Step 1: Diagnose Root Cause and Purchase the Correct Part

Do not guess! Use a professional-grade scanner to read the specific Diagnostic Trouble Code (DTC). Once you have the code, identify which sensor it refers to—is it upstream or downstream? Is it an AFR or a $text{NO}_text{x}$ sensor? Order the correct OEM or high-quality aftermarket replacement.

Step 2: Prepare the Vehicle and Locate the Sensor

1. Ensure the engine is completely cool. Working on a hot exhaust system is extremely dangerous and can damage new components.

2. Safely lift and secure the truck, if necessary, to gain access beneath the vehicle. Always use high-quality jack stands rated for the vehicle weight.

3. Visually trace the exhaust path to the sensor location. They look like small metal canisters screwed into the piping with a thick wire harness leading away from them.

Step 3: Disconnect the Old Sensor

1. Follow the wiring harness from the sensor back to its nearest connector junction.

2. Carefully disconnect the electrical harness plug. Sometimes these have locking clips that need to be squeezed or slid before pulling apart.

3. Inspect the wiring insulation for any signs of rubbing, melting, or corrosion. If the wiring is damaged, repair it before installing the new sensor.

Step 4: Remove the Old Sensor

1. Fit your specialized oxygen sensor socket onto the hex head of the sensor.

2. Apply steady, firm counter-clockwise pressure to loosen the sensor. Be prepared; sensors can be incredibly tight due to heat expansion and rust.

3. If it won’t budge, a small amount of penetrating oil applied to the threads (being careful not to drip onto the catalyst material) and a short wait time can help.

4. Once loose, unscrew the sensor by hand and remove it.

Step 5: Install the New Sensor

1. Take your new sensor. Most quality replacements come with a factory-applied anti-seize compound on the threads. If yours does not, apply a thin layer of high-temperature anti-seize specifically designed for oxygen sensors to the threads only (do not get any on the sensor tip).

2. Thread the new sensor into the bung by hand first. This prevents cross-threading, which ruins the exhaust pipe threads.

3. Use your torque wrench to tighten the sensor to the manufacturer’s specification—this is usually quite tight, but over-tightening can damage the sensor body or threads. Check your specific vehicle service manual for the exact torque value.

Step 6: Reconnect and Clear Codes

1. Plug the new electrical connector firmly back into its housing until you hear or feel a click.

2. Reconnect the battery.

3. Use your OBD-II scanner to clear the stored trouble codes.

4. Run the engine and drive the vehicle through a few different load cycles (highway, city driving) to allow the ECU to “re-learn” the sensor inputs. The system monitors the sensor output for a few drive cycles before deciding the repair was successful. Check back in a few days; if the light stays off, you succeeded!

Advanced Note: Diesel vs. Gasoline Sensor Differences

While both use sensors to measure exhaust gases, the technologies are tuned differently. Understanding this helps you buy and replace the correct part.

| Feature | Gasoline O2 Sensor (Narrowband) | Diesel AFR Sensor (Wideband) |

|---|---|---|

| Primary Use | Maintaining a perfect 14.7:1 air/fuel ratio for catalyst efficiency. | Calculating precise exhaust gas composition for DPF/SCR management. |

| Operating Voltage/Signal | Switches sharply between 0.1V (Lean) and 0.9V (Rich). | Provides a linear, precise ratio measurement across a wide spectrum. |

| Response Speed | Fast, cycling many times per second. | Generally slower, designed for steady stream analysis rather than rapid switching. |

| Prevalence in System | Crucial for engine control. | Crucial for emissions control compliance. |

Frequently Asked Questions (FAQ) for Beginner Diesel Owners

Q1: If my diesel doesn’t have a DPF or DEF system, does it still have an O2 sensor?

Older, pre-emission diesel engines usually did not have sophisticated oxygen or AFR sensors. They relied more on mechanical injection timing. If your diesel is pre-2004 (US models), it is much less likely to have one, though some heavier-duty trucks might have had early emissions monitoring.

Q2: Can I just unplug a bad $text{NO}_text{x}$ sensor on my diesel truck?

No, you absolutely should not. Unplugging any emissions sensor will immediately trigger a check engine light. Furthermore, modern diesels are programmed to enter “Limp Mode” or refuse to start after a certain number of drive cycles if critical sensors like the $text{NO}_text{x}$ or DPF Pressure sensors report a fault or are missing entirely.

Q3: Is there a difference between a standard O2 sensor and an AFR sensor?

Yes, a big one! A standard (narrowband) O2 sensor tells the computer if the mix is rich or lean. An Air-Fuel Ratio (AFR) sensor, or wideband sensor, measures the exact ratio with high precision and accuracy, which is needed for the complex calculations required by diesel after-treatment systems.

Q4: How long should a diesel oxygen sensor last before it needs replacing?

There is no set lifespan, but generally, they last between 80,000 and 150,000 miles. However, overheating, contamination from oil or coolant leaks into the exhaust, or harsh driving conditions can cause them to fail much sooner.

Q5: Can a bad upstream sensor cause my DPF to clog?

Potentially, yes. The upstream AFR sensor tells the computer the exhaust makeup. If the sensor is faulty and reads too lean, the computer might inject too much fuel to try and compensate, leading to more soot buildup in the DPF than normal. This is why immediate replacement is important.

Q6: Do I need to clear codes after installing a new sensor?

Yes. Even if the new sensor is working perfectly, the old fault code will stay stored in the ECU’s memory. You must use an OBD-II scanner to actively erase the history for the light to go out and for the system to begin normal monitoring again.

Conclusion: Keeping Your Diesel Efficient and Clean

Understanding whether your diesel engine has oxygen sensors—and recognizing that they are often highly specialized AFR or $text{NO}_text{x}$ sensors—removes a lot of the mystery surrounding modern diesel maintenance. These sensors are the eyes and ears of your complex exhaust after-treatment system. While they might seem frustrating when they fail, realizing their purpose empowers you. They are essential for compliance, maximizing your MPG, and preventing highly expensive shutdowns related to DPF or SCR system failures.

By being aware of the signs of failure and following safe procedures when performing checks or replacements, you ensure your diesel plant stays powerful, clean, and reliable for many miles to come. Keep monitoring those codes, respect the exhaust heat, and you’ll master diesel maintenance one system at a time!