Do Oxygen Sensors Cause Rough Idle? Essential Fixes

Yes, faulty oxygen sensors often cause a rough idle. When an O2 sensor fails, it sends incorrect data to your car’s computer, leading to a poor air/fuel mixture that results in noticeable engine shaking, stalling, or poor performance, especially when stopped. Replacing the sensor is often the essential fix we focus on here.

Pinging, shaking, sputtering—these sounds from your engine when your car is stopped can be truly annoying. You might wonder if there is a major engine issue. Often, the culprit is much simpler: a failing oxygen sensor. These small parts are vital for smooth running. When they go bad, your engine struggles to breathe correctly, leading directly to that frustrating rough idle. Don’t worry if this seems technical. I am Monowar Shohag, and I will break down exactly how the oxygen sensor connects to your car’s idle quality. We will look at the signs, confirm the connection, and walk through the straightforward steps you can take to fix this common problem today.

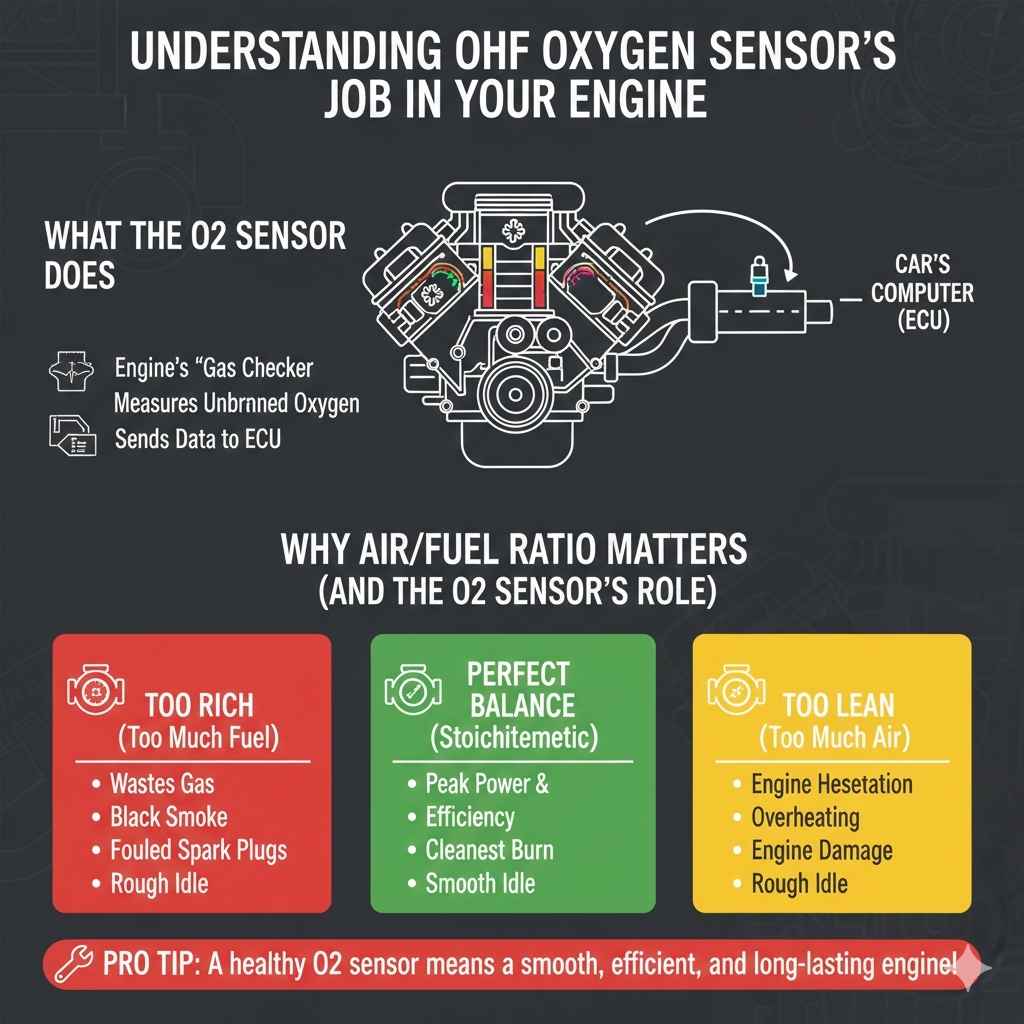

Understanding the Oxygen Sensor’s Job in Your Engine

To know if an oxygen sensor causes a rough idle, we first need to understand what this part actually does. Think of the oxygen sensor—or O2 sensor—as the engine’s tiny gas checker. It lives in your exhaust system. Its main job is to measure how much unburned oxygen is left over after combustion in your engine.

This measurement is crucial. The readings are sent straight to your car’s main brain, the Engine Control Unit (ECU). The ECU uses this data to constantly adjust the air/fuel ratio entering the engine cylinders. For peak performance and efficiency, the mixture needs to be just right—not too rich (too much fuel) and not too lean (too much air).

When the O2 sensor works perfectly, this adjustment happens instantly, keeping your engine running smoothly whether you are cruising on the highway or sitting still at a red light.

The Direct Link: Do Oxygen Sensors Cause Rough Idle?

The answer is almost certainly yes, if other major components are ruled out. A rough idle is one of the most common symptoms of a failing O2 sensor. Here is exactly why this happens:

Why Bad Sensors Lead to Rough Idling

When an oxygen sensor starts to degrade, it provides slow, inaccurate, or completely missing data to the ECU.

- Incorrect Fueling: If the sensor falsely reports that the exhaust gas has too much oxygen (lean condition), the ECU tries to compensate by dumping more fuel into the engine.

- Rich Running: Too much fuel—a rich mixture—means the fuel isn’t burning completely. This leads to poor combustion, wasted gas, reduced power, and the immediate symptom of a rough or shaky idle.

- Sputtering and Stalling: If the ECU can’t get a reliable reading, it guesses. This constant “guessing game” at idle speed causes the engine to run unevenly, leading to shaking, hesitation, and potentially stalling when you stop.

This instability is often most noticeable at idle because the engine relies heavily on precise sensor readings when the throttle is closed (not pressing the gas pedal). At higher speeds, the system has more airflow and fuel volume to smooth things out, masking the underlying sensor issue temporarily.

Identifying the Symptoms: More Than Just a Rough Idle

While a rough idle is the main clue, a failing oxygen sensor usually broadcasts its distress through several other warning signs. Recognizing these together can help you pinpoint the O2 sensor as the likely cause:

- Check Engine Light (CEL): This is the big one. When the sensor provides readings outside the expected range, the ECU stores a Diagnostic Trouble Code (DTC), such as P0133 (O2 Sensor Circuit Slow Response).

- Poor Fuel Economy: If the car keeps running rich because of bad sensor data, you’ll notice yourself visiting the gas station much more often.

- Failing Emissions Test: Excess raw fuel means higher emissions of unburned hydrocarbons. According to the U.S. Environmental Protection Agency (EPA), faulty sensors directly impact pollution control systems and emissions compliance.

- Engine Misfires: A deeply irregular air/fuel mixture can cause the spark plugs to fail to ignite the cylinder charge properly, leading to noticeable misfires, especially during deceleration or at idle.

- Smell of Gas: Excessive unburnt fuel exiting the exhaust can sometimes result in a noticeable gasoline smell when the car is running.

Quick Comparison Table: O2 Sensor vs. Other Idle Issues

Sometimes, other things can cause a rough idle, like bad spark plugs or a vacuum leak. Here’s how the symptoms often differ slightly from an O2 sensor issue:

| Symptom | Likely O2 Sensor Failure | Likely Vacuum Leak | Likely Spark Plug/Coil Issue |

|---|---|---|---|

| Check Engine Light | Common (Specific sensor codes) | Possible (Codes related to lean/rich mixtures) | Very common (Misfire codes P030x) |

| Fuel Economy | Significantly worse (running rich) | Slightly worse or normal | Slightly worse |

| Idle Quality | Shaky, hesitant, often accompanied by rich smell | Very erratic, high idle, or very low idle | Consistent, rhythmic shaking or noticeable “dead spots” |

| Acceleration | Sluggish, hesitant when stepping on the gas | Usually smooth once RPMs increase | Hesitation under load |

Diagnosing the Culprit: Confirming the O2 Sensor

Before you start replacing parts, you need to confirm that the O2 sensor is the actual problem and not just another system mimicking its symptoms. This is where basic troubleshooting comes in handy.

Step 1: Reading the Codes

If the Check Engine Light is on, the first, most crucial step is reading the diagnostic trouble codes (DTCs). You can visit most major auto parts stores for a free code reading, or you can use your own OBD-II scanner.

Look specifically for codes in the:

- P0130 series: These relate to Bank 1 Sensor 1 (the upstream sensor before the catalytic converter) and often indicate slow response, which directly impacts idle control.

- P0150 series: These cover Bank 2 issues (if your engine has two banks, like a V6 or V8).

If you see codes pointing directly to an O2 sensor circuit malfunction, you’ve found your most likely target.

Step 2: Live Data Inspection (The Advanced Check)

If you have an advanced scanner capable of reading “live data,” this is the definitive test. You need to watch the voltage readings from the O2 sensors while the engine is running and fully warmed up.

Here is what you look for:

- Healthy Sensor: A good sensor should rapidly cycle its voltage between 0.1 volts (lean) and 0.9 volts (rich) about once per second.

- Bad Sensor: A failing sensor will show a voltage that is stuck high, stuck low, or moves very slowly (sluggish reporting). If the voltage stays near 0.45V constantly, or barely moves, the sensor is “lazy” and causing your rough idle.

This live data inspection precisely confirms if the sensor is malfunctioning and sending poor control signals.

Essential Fixes: Replacing a Failing Oxygen Sensor

If your diagnosis points to a bad O2 sensor causing that rough idle, replacement is usually the final fix. While this sounds intimidating, replacing an O2 sensor is often a job any beginner can tackle with the right tools and safety precautions.

Safety First: Before You Begin

Working on the exhaust system means dealing with heat, rust, and high temperatures. Always prioritize safety:

- Let It Cool: Never touch the exhaust manifold or piping when the engine has been running recently. Exhaust components get extremely hot and can cause severe burns. Wait at least 30 minutes after turning the car off.

- Disconnect the Battery: For safety, always disconnect the negative (black) battery terminal before unplugging or connecting any electrical component, including the sensor connector.

- Use Jack Stands: If you need to lift the car to access a sensor, never rely only on a jack. Use properly rated jack stands on level ground.

Tools You Will Need

You do not need a huge toolbox for this job, but you need one specific tool to make it easy:

- New Oxygen Sensor (Make sure it matches your car’s year, make, model, and location—upstream sensors are often different from downstream ones!)

- Oxygen Sensor Socket (This is specialized, usually 22mm or 27mm, with a slot cut out for the wire harness. Essential for easy removal.)

- Ratchet and Extension Bar

- Penetrating Oil (like PB Blaster or WD-40 Specialist Rust Remover Soak)

- Torque Wrench (Highly recommended for correct installation)

- Safety Glasses and Gloves

Step-by-Step Replacement Guide for a Rough Idle Fix

We will focus on replacing the upstream sensor because it has the largest impact on idling and fuel mixture control:

Step 1: Locate and Access the Sensor

The upstream O2 sensor is located in the exhaust pipe before the catalytic converter. On a four-cylinder engine, it is usually screwed directly into the exhaust manifold or the downpipe right after the manifold.

If you are working on a vehicle like the Ford F-150 or similar models, you might need to look up specific diagrams. For reliable information on your specific vehicle assembly, consulting service manuals is always a good practice, such as those maintained by automotive education resources.

Step 2: Disconnect the Wiring Harness

Trace the wire coming off the old sensor up to where it plugs into the main wiring loom of the car. Unclip the plastic connector. This usually involves pressing a small tab or lever. Be gentle; the plastic clips can be brittle.

Step 3: Apply Penetrating Oil

This is the step that builds confidence! Exhaust bolts and sensors are often seized due to heat and rust. Spray a liberal amount of penetrating oil directly onto the threads where the sensor screws into the pipe. Let it soak for at least 15 minutes. This prevents snapping the sensor body when you try to turn it.

Step 4: Remove the Old Sensor

Fit your specialized O2 sensor socket over the sensor head. Attach your ratchet. Turn counter-clockwise to loosen. You may need to use a breaker bar or apply significant force initially. Once it breaks free, it should unscrew relatively easily.

Pro Tip: If the sensor is stubborn, run the engine for just 2–3 minutes to slightly warm the pipe (not hot enough to burn you!), then shut it off and immediately apply the penetrating oil again. The slight expansion can help break the rust bond.

Step 5: Prepare the New Sensor

Crucially: New oxygen sensors must be installed dry. Do not apply anti-seize compound to the threads unless the manufacturer explicitly tells you to. Most modern sensors come with a protective cap or coating on the threads that acts as a thread sealant or lubricant.

If you accidentally got grease or oil near the tip (the part that goes into the exhaust), wipe it off with a clean cloth.

Step 6: Install the New Sensor

Hand-thread the new sensor into the exhaust port. Turn it clockwise until it seats snugly. Once it stops by hand, use your torque wrench to tighten it to the manufacturer’s specification. Typically, this is around 30–40 ft-lbs, but check your manual! Overtightening can damage the sensor or the exhaust bung.

Step 7: Reconnect and Test

Plug the new sensor’s wiring harness securely back into the main loom. Reconnect the negative battery terminal.

Start the engine. The ECU needs time to relearn its parameters with the new sensor data. You might notice an immediate improvement in idle quality. Drive the car normally for a few cycles. The Check Engine Light should turn off on its own shortly after the ECU confirms the new sensor is functioning correctly.

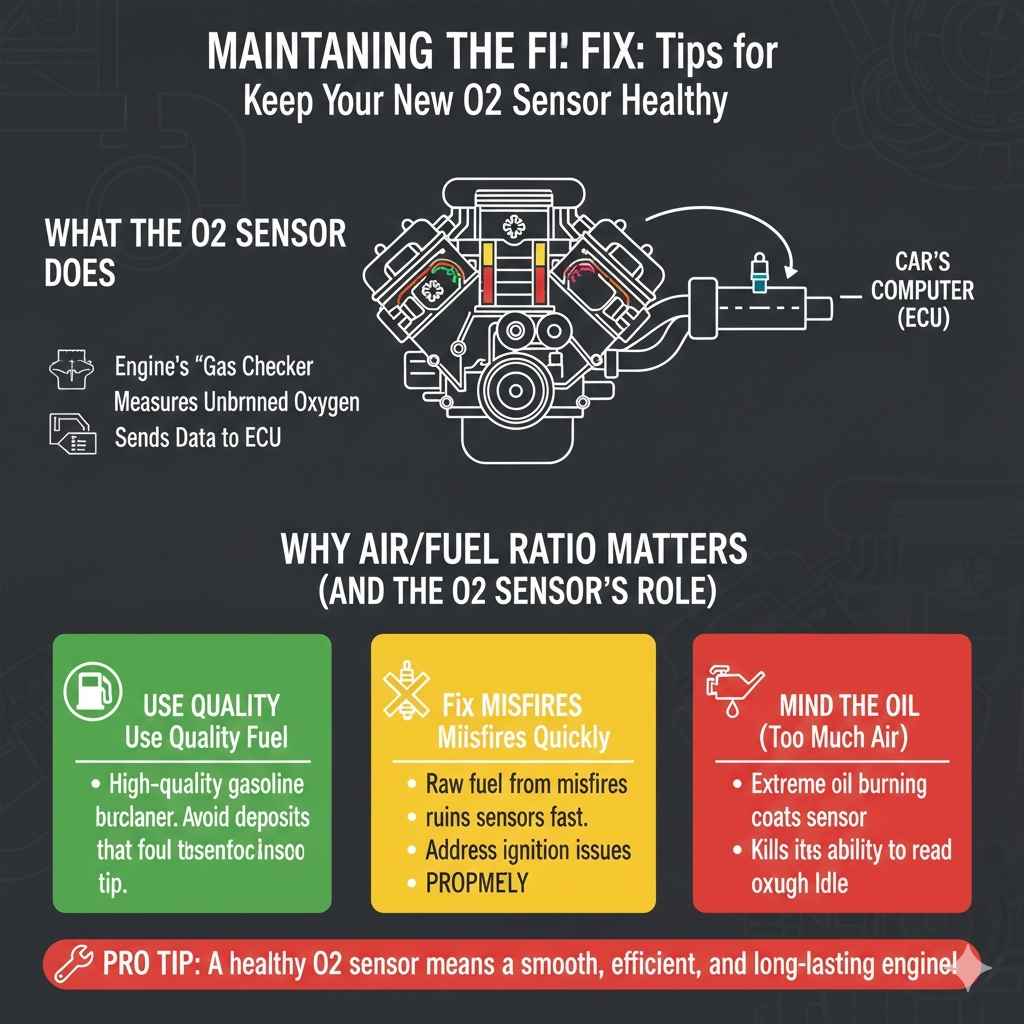

Maintaining the Fix: Tips for Longevity

Replacing the sensor fixes the rough idle caused by the faulty part. However, to keep your new sensor—and your whole exhaust system—running well, consider these maintenance tips:

- Use Quality Fuel: High-quality gasoline burns cleaner. Poor quality fuel can leave deposits that prematurely foul the sensor tip.

- Fix Misfires Quickly: If you have ignored spark plug or coil pack issues, the raw fuel washing over the O2 sensors can ruin them quickly. Always address ignition issues before or immediately after replacing sensors.

- Mind the Oil: Extreme oil burning (burning oil internally) introduces silicone and ash into the exhaust stream, which coats the sensor element and kills its ability to read oxygen effectively.

Frequently Asked Questions (FAQ) About O2 Sensors and Rough Idle

Q1: If my O2 sensor is bad, will my car always run rough at idle?

Not always, but usually. When the sensor fails, the car defaults to a safe, pre-programmed setting, which is typically a “rich” mixture. This rich setting often causes a rough, shaky idle, but sometimes the car can idle just a little unevenly until the Check Engine Light comes on.

Q2: Can I drive my car with a bad oxygen sensor?

You can, but it is not recommended for long periods. The rough idle might make driving uncomfortable, and critically, running too rich wastes a lot of fuel and can damage your catalytic converter over time, leading to a much more expensive repair.

Q3: How long does it take for the Check Engine Light to go off after replacing the sensor?

It varies by car. Most modern vehicles will turn the light off immediately if the new sensor reports perfect data. For others, it may take several complete drive cycles (starting the car when cold, warming it up, shutting it off) before the ECU resets the warning. If it stays on after three full days of driving, have the codes re-scanned.

Q4: Is the upstream or downstream O2 sensor more likely to cause rough idle?

The upstream sensor (Sensor 1, located before the catalytic converter) is the primary one responsible for controlling the air/fuel ratio for engine combustion. A failure here almost always leads to rough idle and poor performance.

Q5: Does a vacuum leak cause the same symptoms as a bad O2 sensor?

They share the rough idle symptom, but the underlying cause is different. A vacuum leak lets unmetered air enter the engine, causing a lean condition. A bad O2 sensor sends bad data, and the computer responds by adding too much fuel, causing a rich condition. They feel similar while idling but require different fixes.

Q6: Should I buy OEM or aftermarket O2 sensors?

For best results, especially when fixing a rough idle, many mechanics suggest using Original Equipment Manufacturer (OEM) sensors or high-quality direct replacements (like Denso or Bosch). Cheaper aftermarket sensors sometimes provide inaccurate voltage signals, leading to poor long-term performance or a rough idle that returns quickly.

Q7: What does it mean when the O2 sensor reading is stuck low?

A low reading (near 0.1V) means the sensor thinks the exhaust is running very lean (too much air). The ECU then commands the injectors to add significantly more fuel to compensate, leading to a very rich running condition, which directly translates into a sputtering or rough idle.

Beyond the Sensor: What If the Idle Stays Rough?

If you have replaced the oxygen sensor, cleared the codes, and your engine still idles roughly, it is time to look at other components tied to the Air/Fuel Control Loop. Your initial diagnosis was smart, but sometimes the sensor was a symptom of a larger issue, or another part failed simultaneously.

Checking the Usual Suspects After an O2 Sensor Swap

- Mass Air Flow (MAF) Sensor: This sensor measures the volume of air entering the engine. If it’s dirty or failing, it sends bad data, causing the ECU to miscalculate the fuel needed, leading to a rough idle similar to an O2 sensor failure. Cleaning or replacement might be necessary.

- Idle Air Control (IAC) Valve: On older cars without electronic throttle bodies, the IAC valve manages air bypass when your foot is off the pedal. If it’s clogged with carbon, it can’t manage the small amount of air needed for a steady idle.

- Vacuum Leaks: As mentioned before, small tears in rubber hoses around the intake manifold, brake booster, or PCV valve system let in unmetered air, leaning out the mixture unpredictably and causing shaking at idle.

- Spark Plugs and Coils: A weak spark on one cylinder will always cause an uneven idle because that cylinder isn’t firing correctly, throwing the entire engine balance off.