Do Furnace Intake and Exhaust Pipes Require Maintenance? Essential Guide

Yes, furnace intake and exhaust pipes absolutely require maintenance. Regular checks and simple cleaning can prevent serious issues, improve efficiency, and ensure your heating system runs safely and reliably all winter long.

Ever wonder about those pipes sticking out of your furnace? You know, the ones that bring fresh air in and carry the burnt stuff out? Many homeowners completely overlook them, yet they’re super important for your furnace to work well and safely. Ignoring them can lead to big headaches, like your furnace not heating your home or, even worse, dangerous gas leaks. But don’t worry, keeping these pipes in good shape is easier than you might think! This guide will walk you through everything you need to know to keep your furnace running smoothly and safely, without any confusing jargon.

We’ll cover what these pipes do, why they need attention, and exactly how to check them. You’ll feel confident knowing you’re taking care of a critical part of your home’s heating system. Stick around, because we’re about to demystify your furnace pipes!

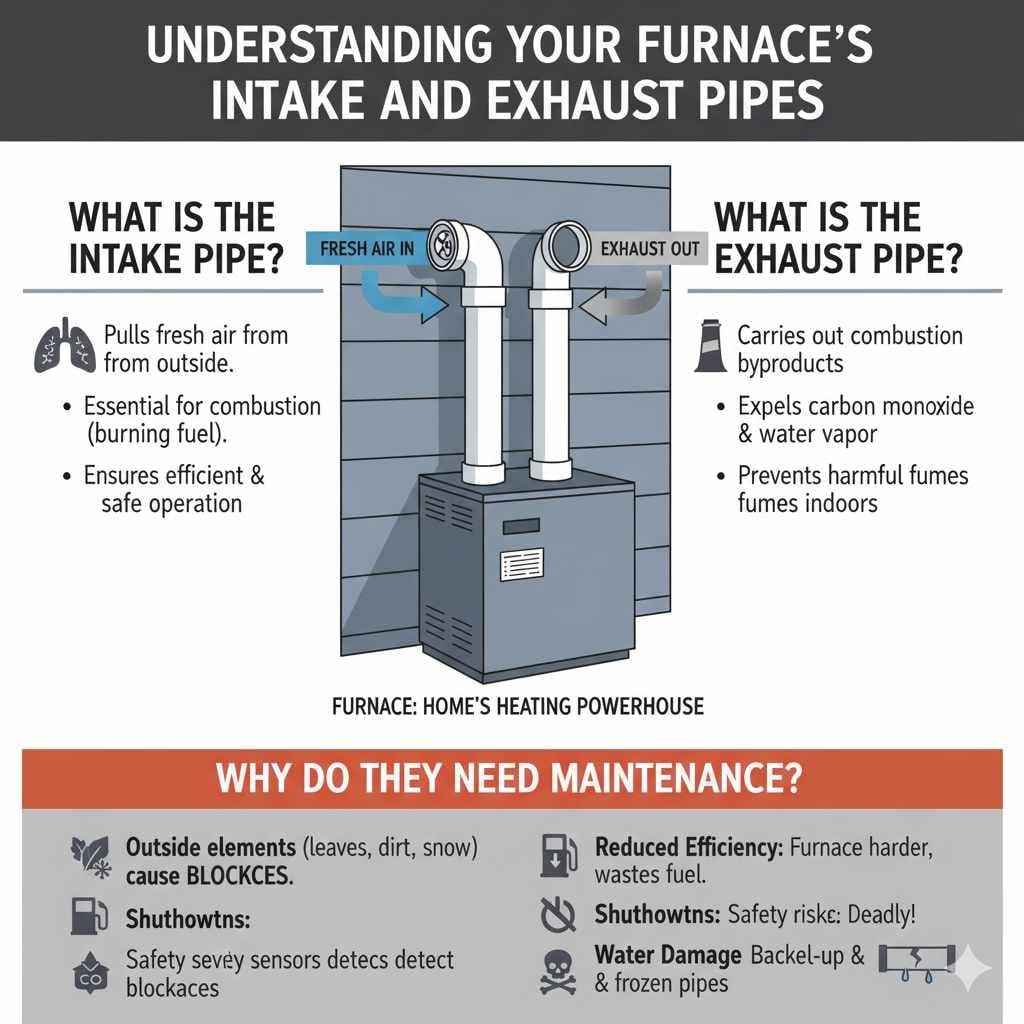

Understanding Your Furnace’s Intake and Exhaust Pipes

Think of your furnace like a car engine. It needs air to burn fuel and it needs to get rid of the fumes. That’s where the intake and exhaust pipes come in. They are the vital “lungs” and “ventilation system” for your home’s heating powerhouse.

What is the Intake Pipe?

The intake pipe’s job is pretty straightforward: it pulls in fresh air from outside your house. This oxygen is essential for the burning process inside your furnace. Without enough fresh air, the combustion wouldn’t be complete, and your furnace wouldn’t run efficiently – or safely.

What is the Exhaust Pipe?

Once the fuel is burned, the exhaust pipe’s mission is to safely carry all the byproducts of combustion – like carbon monoxide and water vapor – out of your home. It’s crucial that this pipe is clear and connected properly, so no harmful fumes can creep back into your living space.

Why Do They Need Maintenance?

Over time, outside elements can cause trouble for these pipes. Think about it: rain, snow, leaves, dirt, even bird nests can find their way to or into these pipes. If they get blocked, your furnace can’t get the air it needs, or the dangerous exhaust can’t escape. This can lead to:

- Reduced Efficiency: A blocked intake means less oxygen, making the furnace work harder and use more fuel.

- Shutdowns: Many modern furnaces have safety sensors that will shut the system down if they detect a blockage in the exhaust.

- Carbon Monoxide Leaks: This is the most serious risk. If the exhaust pipe is blocked or damaged, deadly carbon monoxide could leak into your home.

- Water Damage: Blocked exhaust pipes can sometimes cause water to back up and freeze, damaging the pipe or your home.

Common Issues with Furnace Intake and Exhaust Pipes

These pipes are exposed to the elements, so they can encounter a variety of problems. Knowing what to look for is the first step in preventing them.

Blockages

This is probably the most common issue. Things like:

- Leaves and Debris: Especially in the fall, leaves can get sucked into intake pipes or block exhaust openings.

- Animal Nests: Birds, squirrels, or rodents might decide these pipes are cozy spots for their homes.

- Snow and Ice: In colder climates, snow can pile up and block the openings, and ice can form.

- Dirt and Dust Accumulation: Over months, dust and grime can build up, restricting airflow.

Corrosion and Rust

Many furnace pipes, especially older metal ones, are susceptible to rust. This can weaken the pipe, create holes, and lead to leaks. The vapors carried through the exhaust pipe can be corrosive, contributing to this over time.

Loose Connections

The pipes are usually connected to your furnace and sometimes to each other. If these connections become loose, it can allow exhaust gases to escape into your home or reduce the efficiency of the airflow.

Damaged Pipes

Physical damage from falling branches, lawnmowers, or even just wear and tear can crack, dent, or puncture the pipes, compromising their function.

Do Furnace Intake and Exhaust Pipes Require Maintenance? Essential Guide to Checks and Care

So, to answer the big question clearly: Yes, furnace intake and exhaust pipes definitely need maintenance! It’s not a complex job, and most of it can be done by you with just a few simple tools and a bit of care. Regular checks are key to prevent issues before they become serious problems.

How Often Should You Check Them?

A good rule of thumb is to inspect your furnace’s intake and exhaust pipes at least twice a year. The best times are typically in the spring, after the heating season ends, and again in the fall, before you start using your furnace regularly. This ensures they’re clear and ready for action.

Step-by-Step Guide: Checking Your Furnace Pipes

This guide is designed for beginners. Safety first! If you’re uncomfortable with any step or notice anything seriously wrong, call a professional HVAC technician immediately.

Step 1: Preparation and Safety

Before you start, make sure your furnace is turned OFF. Find the power switch, which is usually a light switch near the furnace itself, or the breaker for the furnace in your electrical panel. It’s also a good idea to wear gloves to protect your hands.

Step 2: Locate the Pipes

These pipes are usually located on the side or back of your furnace. Modern high-efficiency furnaces often have two PVC pipes sticking out:

- One pipe is slightly larger and often white (the intake pipe).

- The other is usually smaller, often gray or black (the exhaust pipe).

Older furnaces might have a single, larger metal pipe for the exhaust.

Step 3: Visual Inspection of the Exterior

Walk around the outside of your home where the pipes terminate. Look for:

For Intake Pipes:

- Any visible blockages like leaves, dirt, or debris at the opening.

- Signs of animal intrusion (nesting materials).

- Damage to the pipe itself.

For Exhaust Pipes:

- Any blockages, especially snow, ice, leaves, or debris.

- Signs of rust or corrosion, particularly on metal pipes.

- Deterioration or cracks in PVC pipes.

- Any signs that the pipe is loose or pulling away from the wall.

Step 4: Clearing Exterior Blockages

If you see debris at the opening, gently remove it. You can use your gloved hands, a soft brush, or a vacuum cleaner with a hose attachment. Be careful not to push debris further into the pipe. For stubborn blockages or if you suspect something is lodged deep inside, it’s best to call a professional.

Step 5: Checking the Interior (If Accessible and Safe)

Some homeowners might want to check a short distance into the pipe. This is generally easier with PVC pipes. If you can safely reach a few inches into the opening, feel for:

- Any foreign objects.

- Any buildup of dust or condensation.

Important Note: Do NOT insert anything deep into the exhaust pipe, especially if it’s a metal pipe or you have an older furnace. You could dislodge a critical connection or push a blockage further in. Forcing things can cause damage. If the interior seems blocked or you suspect a deep blockage, call a professional HVAC technician.

Step 6: Inspecting the Connections

Look closely at where the pipes connect to your furnace. Ensure there are no obvious gaps, cracks, or signs of leakage. If you see loose fittings, do not attempt to overtighten them yourself, as this can crack the plastic or damage the seal. This is a job for a qualified technician.

Step 7: Testing the System (After Checks)

Once you’ve completed your visual inspection and cleared any exterior debris, you can turn your furnace back on.

Listen for any unusual noises coming from the furnace or the vents.

Check that warm air is coming out of your vents. If your furnace doesn’t turn on, makes strange noises, or doesn’t produce heat, turn it off immediately and call a professional.

Tools You Might Need

For basic exterior checks and cleaning, you won’t need much. Here’s a simple list:

- Work Gloves: To protect your hands.

- Soft Brush: For gently cleaning away debris.

- Vacuum Cleaner (with hose attachment): Useful for sucking away loose dirt and debris.

- Flashlight: To see into darker areas.

- Safety Glasses: To protect your eyes, especially if debris falls.

When to Call a Pro: If you need to reach high pipes, if you suspect internal blockages, or if you are uncomfortable performing any of these checks, it’s always best to hire a qualified HVAC technician. They have the tools and expertise to safely diagnose and fix any issues.

Professional Maintenance vs. DIY

It’s great that you’re learning to be proactive with your home’s heating system! Here’s a breakdown of what you can typically handle versus what’s best left to the experts.

DIY: What You Can Do

- Visual Inspection: Checking for obvious blockages, damage, or loose connections from the outside.

- Exterior Cleaning: Removing leaves, dirt, and debris from the pipe openings.

- Minor Debris Removal: Gently clearing out reachable debris from openings.

Professional Maintenance: When to Call an HVAC Technician

- Annual Furnace Tune-Up: This is highly recommended. A technician will inspect all parts of your furnace, including the intake and exhaust system, in detail.

- Internal Blockage Suspicions: If you hear strange noises, if the furnace is shutting off, or if you can’t see the source of a blockage.

- Pipe Repair or Replacement: If pipes are cracked, rusted through, or loose.

- Gas Leak Concerns: If you smell gas or suspect any issues with the exhaust system’s integrity.

- Complex Systems: If your furnace has a more complex venting setup (e.g., horizontal venting through multiple walls).

Many HVAC companies offer annual maintenance plans that include thorough checks of your entire heating system, which would cover your intake and exhaust pipes. Visiting resources like the ENERGY STAR website can offer valuable tips for finding a reputable contractor.

The Importance of Proper Venting for Safety

This cannot be stressed enough: the exhaust pipe is a critical safety component. Its primary function is to vent dangerous combustion byproducts, most notably carbon monoxide (CO), out of your home. Carbon monoxide is an odorless, colorless gas that can be deadly. If your exhaust vent is blocked or compromised, CO can seep back into your living spaces.

According to the U.S. Consumer Product Safety Commission (CPSC), blocked vents are a significant cause of CO poisoning incidents related to heating equipment. Regular checks, clearing obstructions, and ensuring pipes are intact are essential preventative measures.

Key Safety Practices:

- Never ignore warning signs: Symptoms like headaches, dizziness, nausea, or flu-like feelings can indicate CO poisoning. If you suspect CO, evacuate your home immediately and call emergency services.

- Install CO Alarms: Ensure you have working carbon monoxide detectors on every level of your home, especially near sleeping areas. Test them regularly. You can find more information on CO safety from the CPSC website.

- Annual Professional Inspections: While you can do basic checks, a professional inspection ensures the entire venting system is up to code and functioning correctly.

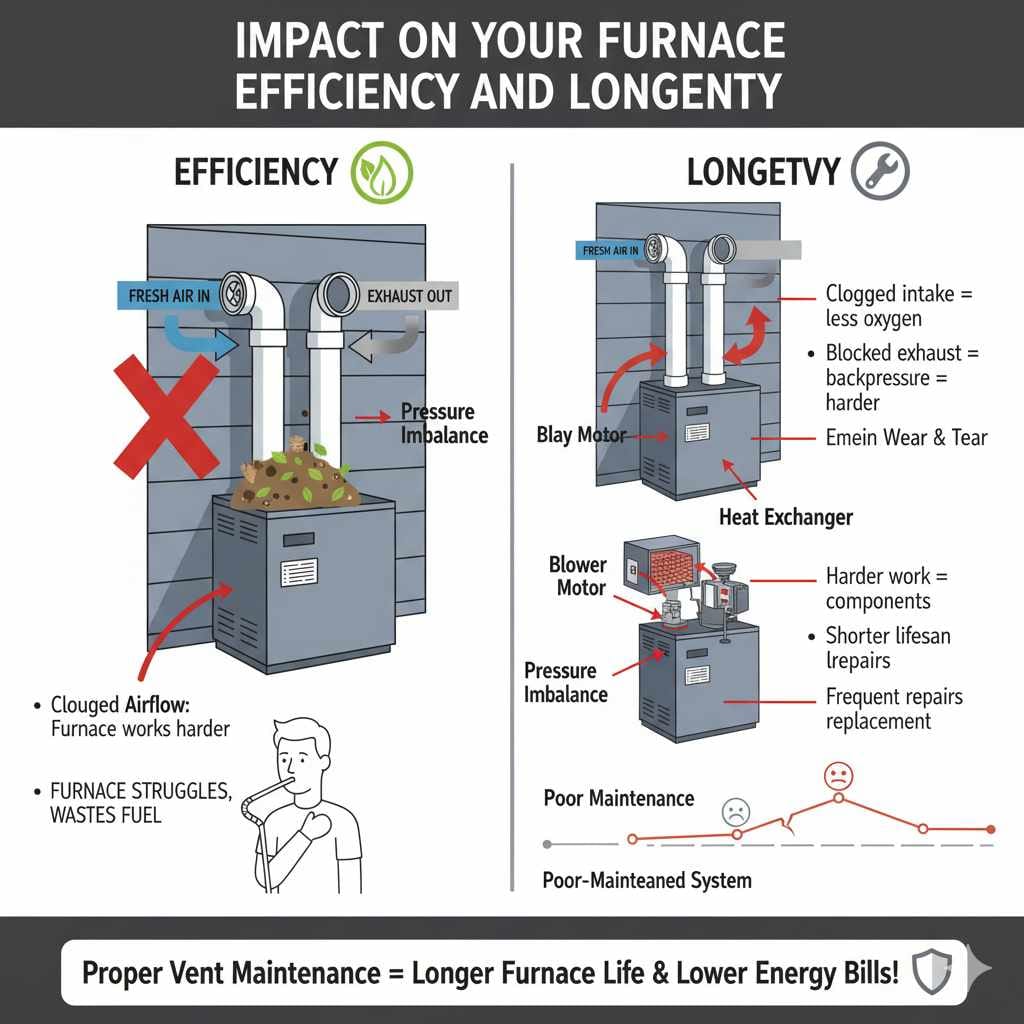

Impact on Furnace Efficiency and Longevity

Maintaining your intake and exhaust pipes isn’t just about safety; it also significantly impacts how well your furnace runs and how long it lasts.

Efficiency

A furnace needs a consistent supply of fresh air (intake) and a clear path to expel exhaust. Any restriction in either pipe disrupts this balance:

- Reduced Airflow: A clogged intake means the furnace struggles to get enough oxygen for efficient combustion. It may run longer to achieve the desired temperature, consuming more energy (gas or electricity) and wasting it.

- Pressure Imbalance: Blocked exhaust can create backpressure, forcing flue gases into the heat exchanger, which can also reduce total system efficiency.

Think of it like trying to breathe through a straw while someone is pinching the other end – it takes a lot more effort and isn’t very effective!

Longevity

When a furnace is forced to work harder due to airflow restrictions, its components are put under more strain. This can lead to premature wear and tear on parts like the blower motor, igniter, and heat exchanger. Over time, this can shorten the overall lifespan of your furnace, leading to more frequent repairs and an earlier need for replacement.

A well-maintained venting system ensures your furnace operates within its designed parameters, reducing stress on its components and contributing to a longer, more reliable service life.

Common Furnace Pipe Materials and What to Expect

The type of material your furnace pipes are made from can influence their maintenance needs and how they age.

| Material | Description | Maintenance Considerations | Typical Lifespan |

|---|---|---|---|

| PVC (Polyvinyl Chloride) | These are the white or gray plastic pipes commonly found on modern high-efficiency furnaces. They are lightweight and relatively durable. | Susceptible to UV degradation if exposed to direct sunlight for extended periods. Can become brittle with age. Ensure connections are secure and not cracked. | Often the lifespan of the furnace itself, but brittle PVC can break. |

| Aluminum | Often used for single-wall or double-wall vent pipes on older or mid-efficiency furnaces. Can be flexible or rigid. | Prone to corrosion, especially in moist environments or if dealing with condensation. Rust holes are a common issue. Requires careful inspection for rust-through. | 15-25 years, depending on environmental conditions and maintenance. |

| Galvanized Steel | Similar to aluminum but often thicker and more robust. Also common on older systems. | Can rust over time, though often more resistant than aluminum. Seams can degrade. The physical integrity of thicker steel provides more resilience. | 20-30 years, generally more durable than aluminum. |

| Stainless Steel | Used in some higher-efficiency systems or as a liner in masonry chimneys. Very resistant to corrosion. | The most durable option. Minimal risk of rust. Connections must still be secure. | 30+ years; often lasts longer than the furnace. |

For the most up-to-date information on vent pipe materials and code requirements, consulting local building codes or resources from organizations like the International Code Council (ICC) can be beneficial.

Signs Your Furnace Pipes Need Immediate Professional Attention

While you can perform basic checks, some signs indicate a problem that requires an expert. Don’t delay if you notice any of these:

- Smell of Gas: This is the most critical warning sign. Turn off your furnace immediately and leave the house. Call your gas utility company or 911 from a safe location.

- Sooting or Staining: Black soot or discoloration around the pipe connections or on the exterior of the pipe can indicate a leak or incomplete combustion.

- Unusual Noises: Rattling, banging, or whistling sounds from the furnace or venting system could point to loose components or obstructions.

- Furnace Shutting Off Repeatedly: Many modern furnaces have safety features that shut them down if they detect venting issues.

- Visible Deterioration: Significant rust, holes, cracks, or sagging in the pipes.

- Condensation Issues: Excessive condensation on or around the pipes, especially in cold weather, could indicate a problem with the system or insulation.

When in doubt, always err on the side of caution. Your safety and home’s comfort are paramount.