Are Manifold Clamps to Exhaust Pipe Worth It: Essential Guide

Yes, using manifold clamps on your exhaust pipe is absolutely worth it for a secure, leak-free connection that improves performance and prevents costly future repairs. This guide breaks down why and how!

Hey there, fellow car enthusiasts! Ever noticed a funny noise from your exhaust, or maybe just wondered about the best way to connect different parts of it? It’s a common puzzle, especially when you’re first getting to know your car’s underbelly. One of those pieces you might encounter is the manifold clamp. It might seem small, but this little guy plays a big role in keeping your exhaust system happy and healthy. We’re going to break down exactly what manifold clamps are, how they work, and whether they’re the right choice for your exhaust pipe. Don’t worry, we’ll keep it simple and straightforward, just like a good mechanic would explain it.

What Exactly is an Exhaust Manifold Clamp?

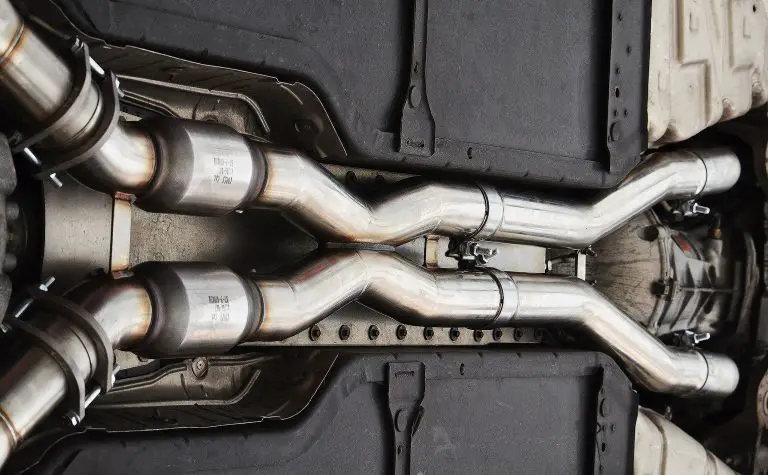

Let’s start with the basics. Your car’s exhaust system is a series of pipes designed to carry harmful gases away from the engine and out into the atmosphere. The exhaust manifold is the first part of this system, bolted directly to your engine block. It collects exhaust gases from the cylinders and funnels them into a single pipe, which then leads to the rest of your exhaust system (like the catalytic converter, muffler, and tailpipe).

Now, how do these parts connect? Sometimes, an exhaust manifold is a single piece, and sometimes it’s in two sections that need to be joined together. This is where manifold clamps come into play. A manifold clamp is a specialized piece of hardware used to securely join two sections of an exhaust manifold or to connect the exhaust manifold to the first section of the exhaust pipe. Think of it like a strong, metal hug that holds these critical pieces tightly together.

These clamps are typically made of durable metal, like stainless steel or mild steel, and are designed to withstand the extreme heat and vibrations common in the exhaust system. They often consist of a U-shaped bolt, a saddle or bridge, and nuts. When tightened, the clamp forces the two pipe sections together, creating a tight seal.

Why Connect Exhaust Manifold Sections?

You might be wondering why an exhaust manifold would even be made in two sections. There are a few good reasons for this design choice:

- Manufacturing Ease: Producing a complex, high-temperature metal part in multiple pieces can sometimes be easier and more cost-effective than casting or fabricating a single, massive piece.

- Engine Design Flexibility: In some engine layouts, having a split manifold can offer advantages in terms of packaging and routing exhaust gases efficiently.

- Aftermarket Options: Sometimes, performance aftermarket exhaust manifolds are designed in sections to allow for easier installation or specific performance gains.

Regardless of why it’s designed that way, the connection needs to be strong and leak-proof. That’s where our manifold clamps shine!

How Do Manifold Clamps Work to Seal Exhaust Pipes?

The magic of a manifold clamp lies in its simple yet effective design. When you fit two pipe ends together and apply the clamp around them, tightening the nuts on the U-bolt does a couple of important things:

- Compression: The U-bolt pulls the two ends of the pipes firmly against each other. This physical pressure is key to creating a seal.

- Sealing Surface: Ideally, the ends of the pipes are designed to mate together with a clean, flat surface. The clamp’s pressure ensures these surfaces are pressed together tightly.

- Gasket Assistance (Sometimes): In many exhaust connections, a gasket is used between the two parts. This gasket acts as a crushable layer to fill any microscopic imperfections on the pipe mating surfaces, ensuring a complete seal. The manifold clamp’s job is to compress this gasket effectively. You can learn more about exhaust gaskets and their importance from resources like Federal-Mogul’s technical information regarding sealing materials, which often applies to exhaust systems too.

The result is a robust connection that prevents exhaust gases from escaping at the manifold junction. Leaks here can be problematic, leading to performance issues and that dreaded “ticking” sound.

Are Manifold Clamps to Exhaust Pipe Worth It? The Pros and Cons

So, the million-dollar question: are these clamps worth the investment and effort? Let’s break down the advantages and disadvantages to help you decide.

Pros of Using Manifold Clamps

When used correctly, manifold clamps offer significant benefits:

- Secure Connection: This is their primary job. They provide a strong, reliable way to join exhaust manifold sections or connect the manifold to the downpipe, preventing parts from vibrating loose.

- Leak Prevention: A tight seal is crucial. Manifold clamps, especially when used with a proper gasket, effectively stop exhaust leaks at the connection point. Leaks can reduce engine performance and send toxic fumes into the cabin.

- Performance Improvement: Leaks in the exhaust system, particularly near the engine, can disrupt the flow of exhaust gases. This can throw off oxygen sensor readings (leading to poor fuel economy) and reduce overall engine efficiency. A leak-free connection helps the engine breathe and perform as intended.

- Cost-Effective Repair: If your existing manifold connection is failing, replacing broken bolts or a worn clamp with a new manifold clamp is often a much cheaper solution than replacing the entire exhaust manifold.

- Ease of Installation (Relatively): Compared to welding, installing a clamp is a straightforward DIY job for most car owners with basic tools.

- Ease of Disassembly: If you ever need to separate the exhaust sections for maintenance or replacement, clamps make this much easier than cutting and re-welding.

- Durability: High-quality manifold clamps are made from strong materials capable of withstanding the harsh undercar environment – heat, vibration, and exposure to road debris and moisture.

Cons of Using Manifold Clamps

While generally beneficial, there are a few potential downsides to consider:

- Can Loosen Over Time: Extreme vibration and thermal cycling can eventually cause the clamp’s nuts to loosen if not properly torqued or secured (e.g., with lock washers or thread locker). Periodic checks are a good idea.

- Can Rust/Corrode: If you live in an area with heavy road salt use or high humidity, “mild steel” clamps can eventually rust through, compromising their integrity. Stainless steel clamps are a better long-term investment in these environments.

- Requires Proper Seating: If the pipe ends are damaged, corroded, or not perfectly aligned, even a tight clamp might not create a perfect seal. Surface preparation is key.

- May Not Be a Permanent Fix for Damaged Pipes: If the pipes themselves are severely damaged, rusted, or warped at the connection point, a clamp can only do so much. In such cases, pipe repair or replacement might be necessary.

When Should You Use Manifold Clamps?

Manifold clamps are most commonly used in these scenarios:

- Joining a Two-Piece Exhaust Manifold: As mentioned, if your car’s exhaust manifold is designed in two halves, clamps are essential for connecting them.

- Connecting the Exhaust Manifold to the Downpipe: Often called a “flange clamp” or “collector clamp,” these secure the first section of the exhaust pipe (the downpipe or front pipe) to the outlet of the exhaust manifold.

- As a Replacement Part: If your existing clamp is broken, rusted, or has lost its clamping force, replacing it is a necessary repair.

- During Exhaust System Upgrades: When installing aftermarket exhaust components, clamps are frequently used to connect new pipes to existing systems or to join sections of a new performance exhaust.

Types of Manifold Clamps and Their Uses

There are a few common designs you’ll see, each suited for slightly different applications:

| Clamp Type | Description | Common Use | Pros | Cons |

|---|---|---|---|---|

| U-Bolt Clamp | The classic design with a U-shaped bolt that goes over the pipes, with a saddle that goes underneath. Nuts are tightened to compress. | Connecting exhaust pipes, downpipes to manifolds, muffler and tailpipe connections. | Strong clamping force, widely available, relatively inexpensive. | Can sometimes pinch or deform pipes if overtightened without proper alignment; can rust if not stainless steel. |

| Saddle Clamp / Band Clamp | A band that wraps around the pipe(s), often with a reinforcing saddle. Secured by bolts that cinch the band tight. | Often used for connecting exhaust pipes where a U-bolt might be difficult to fit (e.g., tight bends) or for sealing slip-fit connections. | Distributes clamping force more evenly around the pipe, less likely to deform the pipe. | Can sometimes be less aggressive in clamping force than a U-bolt; can be more expensive. |

| Flange Clamp / Collector Clamp | Specifically designed to clamp two flanged pipe ends together. They often have a curved shape to match the flange profile. | Connecting exhaust manifolds to downpipes when both have mating flanges. | Provides a very secure and strong seal for flanged connections; designed for this specific application. | Less versatile than universal clamps; requires matching flange designs. |

For most applications directly connecting an exhaust manifold to a pipe, you’ll likely encounter U-bolt or flange-style clamps. It’s important to get the right size that fits snugly around the diameter of both pipes you’re connecting.

Choosing the Right Manifold Clamp

Selecting the correct clamp is vital for a successful installation. Here’s what to look for:

- Material: For longevity, especially in harsh climates, opt for stainless steel. If you’re on a tighter budget and in a dry climate, a good quality mild steel clamp with a protective coating might suffice, but it won’t last as long.

- Size: The clamp must be the correct diameter to fit snugly around both sections of pipe being joined. Measure the outer diameter of your pipes where they will meet. Clamps are typically sized for the pipe’s outer diameter.

- Type: Ensure the clamp type is appropriate for the connection. A flange clamp for flanges, a U-bolt for general pipe-to-pipe connections.

- Quality: Don’t skimp on quality. A cheap, thin clamp will rust out or fail much faster, leading to the same problems you were trying to fix. Look for reputable brands in the automotive exhaust parts industry.

DIY Installation Guide: Replacing a Manifold Clamp (Beginner-Friendly)

Ready to tackle this yourself? It’s a very achievable task. Safety first!

Safety Precautions

- Never work under a vehicle supported only by a jack. Always use sturdy jack stands on a level surface.

- Wear safety glasses to protect your eyes from rust, dirt, and debris.

- Wear gloves to protect your hands.

- Ensure the exhaust system is completely cool before starting.

Tools You’ll Need

- New exhaust manifold clamp (the correct size and type)

- New exhaust gasket (if applicable)

- Wrench or socket set (to fit the clamp nuts)

- Penetrating oil (like WD-40 or PB Blaster)

- Wire brush

- Jack and jack stands

- Wheel chocks

- Torque wrench (optional but recommended for precise tightening)

Step-by-Step Installation

- Prepare the Vehicle: Park your car on a level surface. Engage the parking brake and place wheel chocks behind the rear wheels. If you need to lift the vehicle for access, use a jack and securely place jack stands under the frame rails or designated lifting points.

- Locate the Clamp: Identify the exhaust manifold clamp that needs replacing. It’s usually the connection point right after the engine’s exhaust manifold.

- Apply Penetrating Oil: Spray the nuts and bolts of the old clamp generously with penetrating oil. Let it sit for at least 10-15 minutes (or longer if they’re very rusty) to help loosen things up.

- Remove the Old Clamp: Using an appropriate wrench or socket, carefully loosen and remove the nuts from the old clamp. If the bolts are seized, you might need to carefully cut them off with a reciprocating saw or angle grinder (wear appropriate safety gear if doing this).

- Clean the Connection Area: Once the old clamp is off, use a wire brush to thoroughly clean the ends of both pipes. Remove all rust, dirt, and old gasket material. A clean, smooth surface is essential for a good seal. Some sources, like those from the SEMA Show’s educational content, highlight the importance of surface preparation for bonding and joining metals, which directly applies here.

- Inspect Pipes and Install Gasket: Check the ends of the pipes for any significant damage, cracks, or warping. If the pipes are in good condition, place a new exhaust gasket (if your connection uses one) onto the mating surface of one of the pipes.

- Position the New Clamp: Slide the new manifold clamp over the two sections of pipe, ensuring it’s centered over the joint.

- Tighten the Clamp: Start tightening the nuts on the new clamp evenly, alternating between sides (if it’s a U-bolt) to ensure equal pressure. Tighten them until you feel firm resistance.

- Torque to Specification (Recommended): If you have a torque wrench, find the recommended torque specification for your clamp size and vehicle (consult your service manual or the clamp manufacturer’s recommendations). Overtightening can damage the pipes or clamp, while undertightening will lead to leaks. For many U-bolt style clamps, torque is typically in the range of 25-50 ft-lbs, but always verify.

- Final Check: Double-check that the clamp is centered and securely fastened.

- Lower the Vehicle: Carefully remove the jack stands and lower the vehicle.

- Start the Engine: Start your car and listen for any exhaust leaks around the connection. You should hear a smooth exhaust note, free of ticking or hissing sounds.

Congratulations! You’ve successfully replaced your exhaust manifold clamp.

Troubleshooting Common Issues

Even with the best intentions, you might run into a snag. Here are a few common issues and how to solve them:

- Persistent Leaks: If you still hear a leak after installing the clamp, double-check:

- Clamp Tightness: Are the nuts fully tightened?

- Gasket Condition: Was the gasket damaged during installation? Is it the correct type and size?

- Pipe Condition: Are the pipe ends damaged, corroded, or warped? If so, the pipe may need to be repaired or replaced.

- Clamp Alignment: Is the clamp perfectly centered on the joint?

- Clamp Won’t Tighten Properly: This often happens if the threads on the bolts are stripped or if the clamp is the wrong size for the pipes.

- Rattling/Noise: Sometimes, a clamp itself can become a source of noise if it’s slightly loose or if it’s vibrating against another part of the chassis. Ensure all fasteners are tight and that the clamp has clearance.

FAQ: Your Questions About Manifold Clamps Answered

Q1: How often should I inspect my exhaust manifold clamps?

A1: It’s a good idea to inspect them at least once a year, or whenever you have your vehicle on a lift for other maintenance. Look for signs of rust, looseness, or damage.

Q2: Can I reuse an old exhaust manifold clamp?

A2: It’s generally not recommended. Clamps are designed to be torqued once to create a reliable seal. Reusing a clamp can lead to a weaker seal or breakage.

Q3: What’s the difference between exhaust clamps and muffler clamps?

A3: While both are used to join exhaust components, “manifold clamps” are specifically designed for the high-heat, high-pressure area near the engine, often to join manifold sections or connect the manifold to the downpipe. Muffler clamps are typically used for connecting pipes further down the exhaust system, which experience lower temperatures and pressures.

Q4: Do I always need a gasket with a manifold clamp?

A4: Most mating surfaces on exhaust manifolds and downpipes are designed to work with a gasket to ensure a leak-free seal. While some very specific slip-fit connections might not, it’s best practice to use a new.