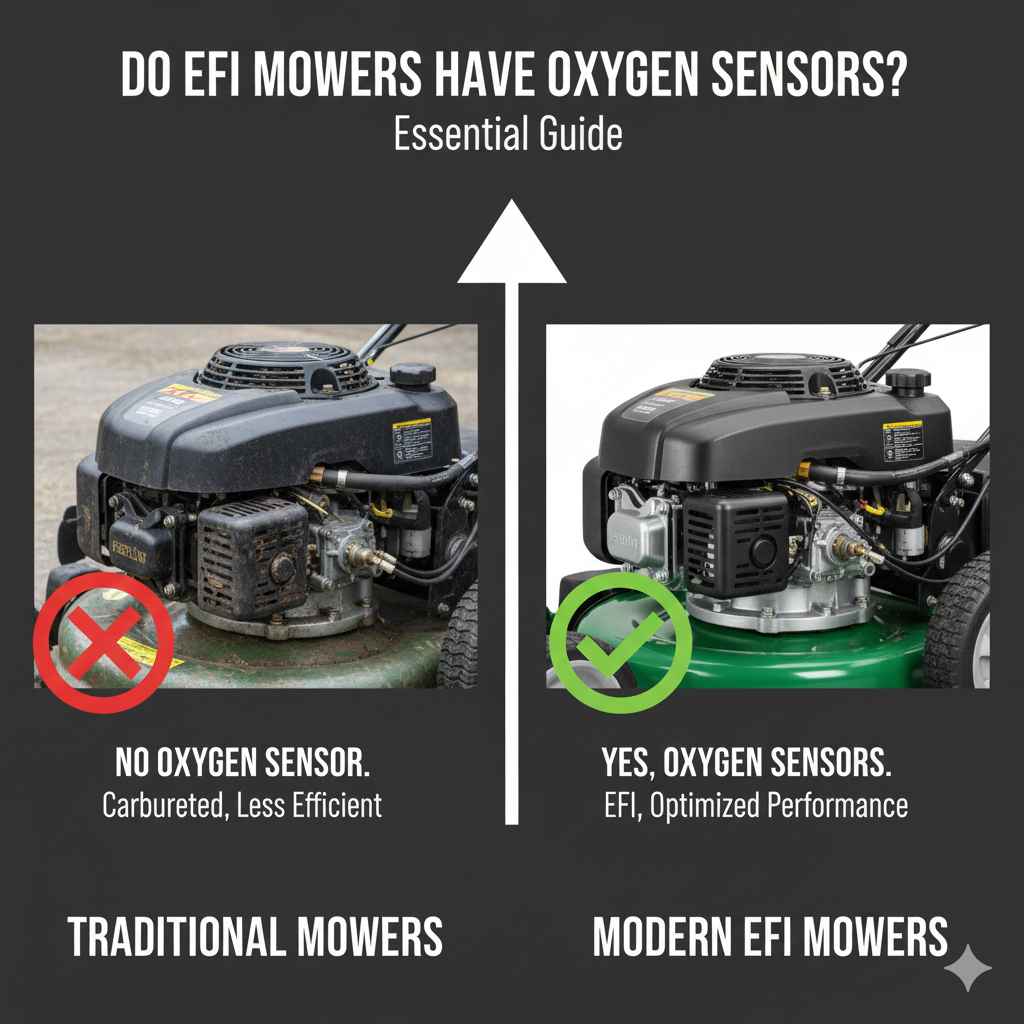

Do EFI Mowers Have Oxygen Sensors? Essential Guide

Yes, many modern Electronic Fuel Injection (EFI) mowers are equipped with oxygen sensors, similar to those found in cars. This sensor monitors exhaust gases to help the engine control unit (ECU) optimize fuel delivery for better efficiency and lower emissions, making it a vital part of the EFI system on your lawn equipment.

It can be confusing when you start looking at the engine on your lawn mower and realize it looks more complex than the older models you are used to. When you hear “EFI,” you might think of your car, not your weekend yard work! Many folks wonder if those fancy new mowers have the same tricky parts found under the hood of a truck, like an oxygen sensor.

If your mower has EFI (Electronic Fuel Injection), it almost certainly has an oxygen sensor, or O2 sensor, working hard to keep your lawn care running smoothly. Not knowing if this tiny part is present can make troubleshooting a real headache.

Don’t worry! I’m Monowar Shohag, and I’m here to clear up all the confusion. We are going to break down exactly what an O2 sensor is, why it matters on your mower, and what you need to know to keep it happy. By the end of this guide, you will understand your EFI mower’s exhaust system perfectly.

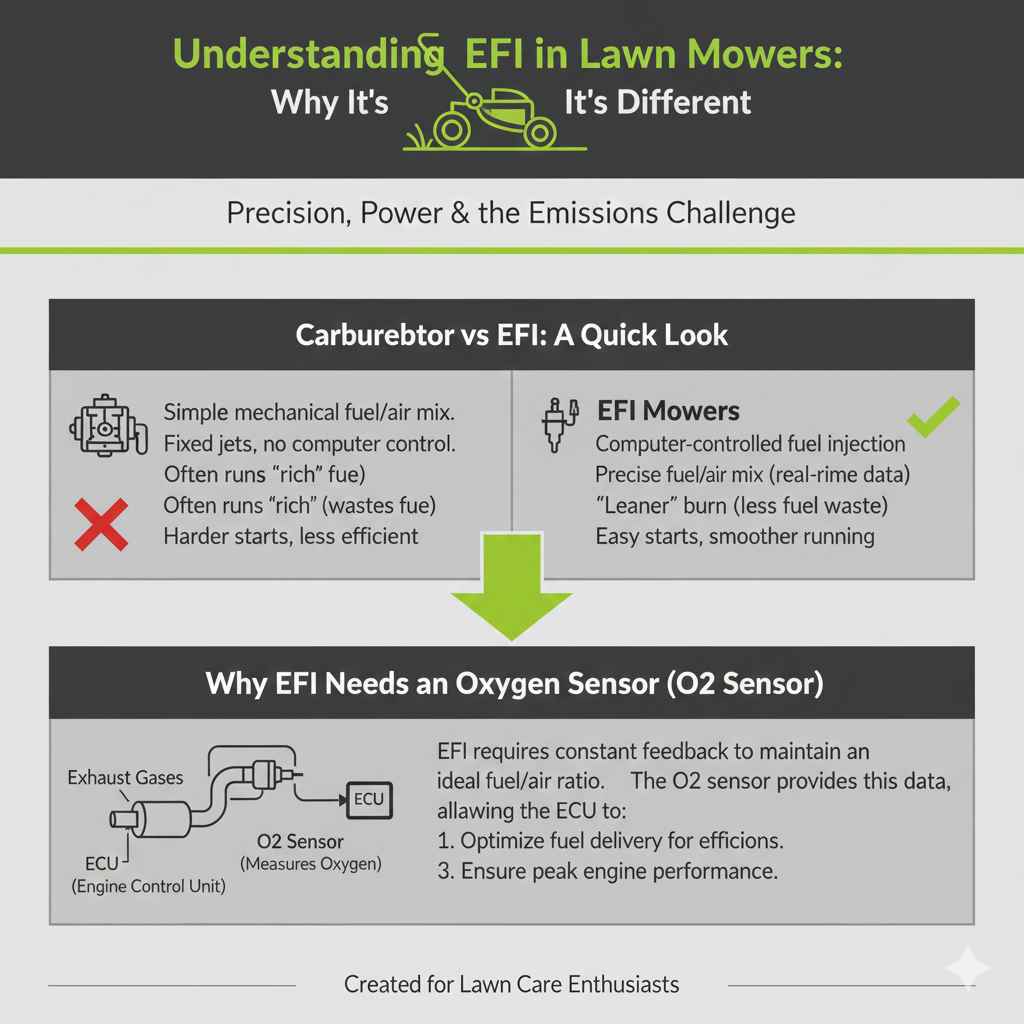

Understanding EFI in Lawn Mowers: Why It’s Different

For years, lawn mowers used carburetors. A carburetor is a simple device that mixes fuel and air mechanically. EFI is the modern upgrade. Think of EFI like a tiny, computer-controlled fuel injector system right on your engine.

Instead of relying on simple mechanics, EFI uses sensors, wiring, and a small computer (the Engine Control Unit or ECU) to precisely measure and deliver the exact amount of fuel needed at any moment. This results in easier starting, smoother running, and less fuel waste. Because the system relies on precise electronic feedback, it needs sensors to know what’s happening inside the engine—this is where the oxygen sensor comes in.

Carburetor vs. EFI: A Quick Look

To understand why an O2 sensor is needed, let’s compare the two systems:

- Carbureted Mowers: Fuel mixture is set by fixed jets and vacuum. They run richer (more fuel) than necessary sometimes “just in case.”

- EFI Mowers: Fuel mixture is constantly adjusted based on real-time data from sensors. This precision demands constant feedback on how well the fuel is burning.

Do EFI Mowers Have Oxygen Sensors? The Definitive Answer

The shortest answer is: Yes, high-quality, modern EFI lawn mowers utilize an oxygen sensor.

If your mower has an EFI system mentioned on the engine housing or in the manual, you should expect to find an O2 sensor tucked into the exhaust manifold or muffler assembly. These sensors are essential gears in making the EFI system work as intended.

What is an Oxygen Sensor and What Does It Do?

In simple terms, the oxygen sensor (often called an O2 sensor) is the engine’s “nose.” It hangs out in the hot exhaust stream leaving the engine and sniffs out how much unburned oxygen remains in that gas.

Why does it care about oxygen? This tells the ECU a huge secret: was the fuel mixture too rich (too much fuel, not enough air) or too lean (too much air, not enough fuel)?

Based on the sensor’s readings, the ECU instantly adjusts how long the fuel injector stays open, ensuring you always have the perfect Ratio (the stoichiometric ratio, around 14.7 parts air to 1 part fuel for gasoline). This perfect balance maximizes power while minimizing harmful emissions and fuel consumption.

Where Would the O2 Sensor Be Located on a Mower?

Unlike cars where the sensor is often right in the exhaust pipe under the car, on a mower, the location is usually much easier to access, though sometimes tucked away:

- Near the Engine Port: It screws directly into the exhaust header pipe, which is the short pipe coming straight out of the engine block.

- Inside the Muffler: On some designs, especially compact zero-turn mowers, the sensor might be threaded into the side of the muffler housing itself.

- Wiring Check: Look for a small, often threaded sensor with a wire harness (usually one or two wires) leading back toward the main wiring loom or the ECU box mounted near the engine.

Here is a quick comparison of where to look:

| Component | Typical Location on EFI Mower | Appearance |

|---|---|---|

| Throttle Body/Injector | On the intake manifold, where air enters the engine. | Larger component with electrical connectors. |

| ECU (Engine Computer) | Often housed in a waterproof box near the battery or starter. | Small black box with many plugs attached. |

| Oxygen Sensor (O2 Sensor) | Screwed into the exhaust manifold or muffler. | Small, threaded metal probe with a wire coming out. |

Why Your EFI Mower Needs an O2 Sensor

The presence of an O2 sensor isn’t just for compliance; it actively improves your mowing experience. Think of it as crucial maintenance that pays you back in performance.

The Three Main Benefits of O2 Sensors on Mowers

These sensors provide three major advantages over older non-feedback carburetor systems:

- Fuel Economy: By ensuring the perfect air-fuel mix, the engine doesn’t waste fuel. You get more acres mowed per tank of gas.

- Emissions Control: EFI systems are designed to meet modern, strict emission standards (like those set by the EPA in the United States). The O2 sensor is the key component that allows the ECU to keep the exhaust clean. For more information on small engine emissions, you can check resources like the Environmental Protection Agency’s guidelines on nonroad engines.

- Consistent Performance: If the air temperature changes, the altitude changes, or the fuel quality varies slightly, the O2 sensor tells the ECU to adjust immediately. This means smoother idling, less hesitation, and reliable power even under heavy load (like tough, thick grass).

What Happens When an O2 Sensor Fails?

A failing O2 sensor is one of the most common culprits behind poor performance in EFI engines. Because the ECU relies on this sensor’s data, if the data stops coming or is wildly inaccurate, the ECU defaults to a “safe mode.”

Safety mode usually means the ECU runs the engine very rich (lots of extra fuel) to prevent damage from running too lean. This leads to:

- Significantly decreased fuel mileage.

- Dark or black smoke coming from the exhaust (a sign of too much fuel).

- Rough idling or difficulty starting.

- Potential for spark plug fouling due to excess carbon buildup.

Servicing and Diagnosing Your EFI Mower O2 Sensor

As a beginner, you don’t need to become an electronics expert, but knowing how to spot a potential problem is fantastic for saving time and money on service calls. Remember, safety first—always disconnect the battery before working near wiring or sensors.

Signs Your O2 Sensor Might Be Bad

Your mower will usually give you clear hints if the sensor is acting up:

- Check Engine Light: Most modern EFI mowers have a diagnostics light—this is your first sign something is electronically wrong.

- Fuel Consumption Spike: If you suddenly need way more gas than normal, the engine is likely running rich due to bad O2 feedback.

- Poor Throttle Response: Hesitation when you push the throttle wide open.

- Fouled Plugs: If you pull your spark plug and it looks black and sooty, this often points to an overly rich condition caused by a faulty sensor telling the ECU to dump too much fuel.

Tools You Might Need for Inspection

If you decide to physically inspect or replace the sensor yourself (which is usually a straightforward swap once you locate it), you’ll need a few simple tools:

- Safety Glasses and Gloves: Always protect your eyes.

- Basic Socket Set or Wrench.

- O2 Sensor Socket: This is a specialized offset box-end wrench designed to grip the sensor body while clearing the wires. You can find good kits online or at hardware stores.

- Torque Wrench (Recommended): To tighten the new sensor correctly without damaging the threads.

- Diagnostic Tool (Optional but Helpful): Some professional-grade mowers come with simple code readers, or you can use basic OBD-II style readers if the manufacturer uses similar connectors, though this is less common on lawn equipment.

Step-by-Step: Checking the O2 Sensor Wiring

Before assuming the sensor is broken, always check the simple stuff first—the wires!

| Step | Action | What to Look For |

|---|---|---|

| 1 | Safety First | Ensure the ignition is off and the battery is disconnected. |

| 2 | Locate the Sensor | Follow the exhaust pipe from the engine head to the muffler. Look for the threaded sensor. |

| 3 | Inspect the Wire | Carefully trace the wire from the sensor back toward the ECU. Look for cuts, abrasions, or signs of heat damage. |

| 4 | Check Connections | Unplug the sensor harness connector (usually by squeezing a locking tab) and check the pins inside for corrosion (green or white powder). Use electrical contact cleaner if necessary. |

| 5 | Test the Sensor (Advanced) | If you have a multimeter, you can test the sensor’s voltage output while the engine is running and warm, but this requires referencing the specific service manual for voltage targets. For beginners, physical inspection and code reading are safer starting points. |

Replacing a Faulty O2 Sensor on Your Mower

If inspection shows the wiring is fine, the sensor likely needs replacement. This is a manageable DIY job.

- Purchase the Correct Part: Get the exact replacement sensor specified for your mower’s engine model. Using the wrong sensor can cause fueling errors.

- Remove the Old Sensor: Use the specialized O2 sensor socket to carefully unscrew the old sensor. It might be tight because it’s exposed to high heat. Turn counter-clockwise.

- Prepare the New Sensor: Many new sensors come with anti-seize compound pre-applied to the threads, or you may need to apply a small amount of high-temperature anti-seize (ensure it doesn’t get on the sensor tip!).

- Install the New Sensor: Screw the new sensor in by hand first to ensure it doesn’t cross-thread. Tighten it gently using the torque wrench to the manufacturer’s specification. Over-tightening can damage the threads in the exhaust.

- Reconnect and Test: Plug the harness back in securely. Reconnect the battery and start the mower. Clearing the diagnostic code, if possible, will confirm the fix.

The Future of Mower Electronics and Sensors

As emissions regulations tighten and manufacturers strive for greater efficiency, the trend for lawn equipment is moving overwhelmingly toward advanced electronic control.

We used to think of complex sensors as only being in high-end vehicles, but now they are becoming standard on everything from industrial zero-turns to high-end residential push mowers. This move means that understanding basic sensor diagnostics, like knowing that an EFI mower does have an O2 sensor, will become essential for routine maintenance moving forward.

Manufacturers are also integrating more sophisticated sensors:

- Knock Sensors: To prevent engine damage from improper combustion timing.

- Intake Air Temperature (IAT) Sensors: To adjust fuel mixture based on air density.

- Throttle Position Sensors (TPS): To tell the ECU exactly how much the operator wants to accelerate.

The O2 sensor remains the most critical sensor for verifying the effectiveness of the combustion process itself, making it the cornerstone of the EFI system’s tuning loop.

FAQ: Beginner Questions About EFI Mower Sensors

Q1: If my mower is EFI but old, does it have an O2 sensor?

A: Early EFI systems, especially those introduced before stricter EPA mandates, might not have included an O2 sensor. If your EFI system is from the last 10–15 years, it almost certainly has one. Check your engine manual for sensor listings.

Q2: Can I just unplug the O2 sensor if I think it is bad?

A: While you can physically unplug it, the engine’s ECU will immediately detect the missing signal and default to the rich “limp mode,” causing poor performance and high fuel use. It’s better to diagnose and replace a confirmed faulty sensor or clear the code after disconnecting it.

Q3: How long should an O2 sensor last on a mower?

A: Oxygen sensors operate in harsh, high-heat environments. While they can sometimes last for thousands of hours, it is common for them to degrade after 5 to 8 years of regular use, especially if the engine runs slightly rich often. If you see performance issues related to fuel economy, suspect the sensor around this age mark.

Q4: Is it expensive to replace the O2 sensor on a mower?

A: Compared to vehicle sensors, mower sensors are generally less expensive. Parts can range from $40 to $100 depending on the brand, and since the replacement is often a simple unscrew and screw-in process, labor costs (if you hire a shop) are usually low.

Q5: Can I clean an O2 sensor instead of replacing it?

A: Some people try to clean them using specialized electronic or sensor cleaning sprays, but success is very mixed. Once the internal ceramics or elements become coated with carbon or lead deposits (if using poor fuel), cleaning rarely restores full accuracy. Replacement is almost always the best long-term solution for a malfunctioning sensor.