Do Heated Oxygen Sensors Go Bad In 30000 Miles: Essential Truth

Quick Summary: While it’s uncommon for a heated oxygen sensor (O2 sensor) to fail completely at just 30,000 miles, premature failure is possible due to severe engine issues, poor fuel quality, or contamination. Most quality sensors are designed to last much longer, often surpassing 100,000 miles with normal use.

Welcome! Dealing with engine lights can be stressful, especially when the culprit seems too new to fail. Many drivers wonder about the lifespan of heated oxygen sensors. You see that check engine light flicker, and you start worrying about big repair bills.

It’s frustrating when a modern car part seems to quit early. But don’t worry! We are going to break down exactly how long these vital sensors should last and why some might fail sooner than expected, even around 30,000 miles.

I’m Monowar Shohag, and I make exhaust maintenance simple. We’ll cover what an O2 sensor actually does, what causes them to fail early, and how you can spot the signs without needing a fancy degree. Stick with me, and we will demystify the mystery of premature O2 sensor failure.

What Exactly Is a Heated Oxygen Sensor (And Why Does It Need Heat)?

To understand why a sensor might fail at 30,000 miles, we first need to know its job. Think of the oxygen sensor, or O2 sensor, as your engine’s air quality checker. It lives right in your exhaust system, sensing how much oxygen is left over after the fuel burns in your cylinders.

The Engine’s Air Quality Reporter

This tiny sensor sends critical data back to your car’s main computer, the Engine Control Unit (ECU). The ECU uses this information to adjust the air-to-fuel ratio perfectly. This perfect mix ensures:

- Maximum fuel economy.

- Low harmful emissions.

- Smooth engine performance.

The Role of the Heater Circuit

When your engine starts cold, the exhaust gas isn’t hot enough for the sensor to work correctly. If the sensor stays cold, it sends slow, inaccurate readings. This wastes fuel and creates more pollution.

That’s where the “heated” part comes in. Modern O2 sensors have a built-in heating element, much like the filament in an old lightbulb. The heater warms the sensor up very quickly—often within seconds of starting the car.

This faster warmup time is vital for meeting modern emissions standards right away. According to the Environmental Protection Agency (EPA), quick emissions control is key to cleaner air, and the heater element makes that possible.

The 30,000-Mile Question: Do Heated O2 Sensors Go Bad This Early?

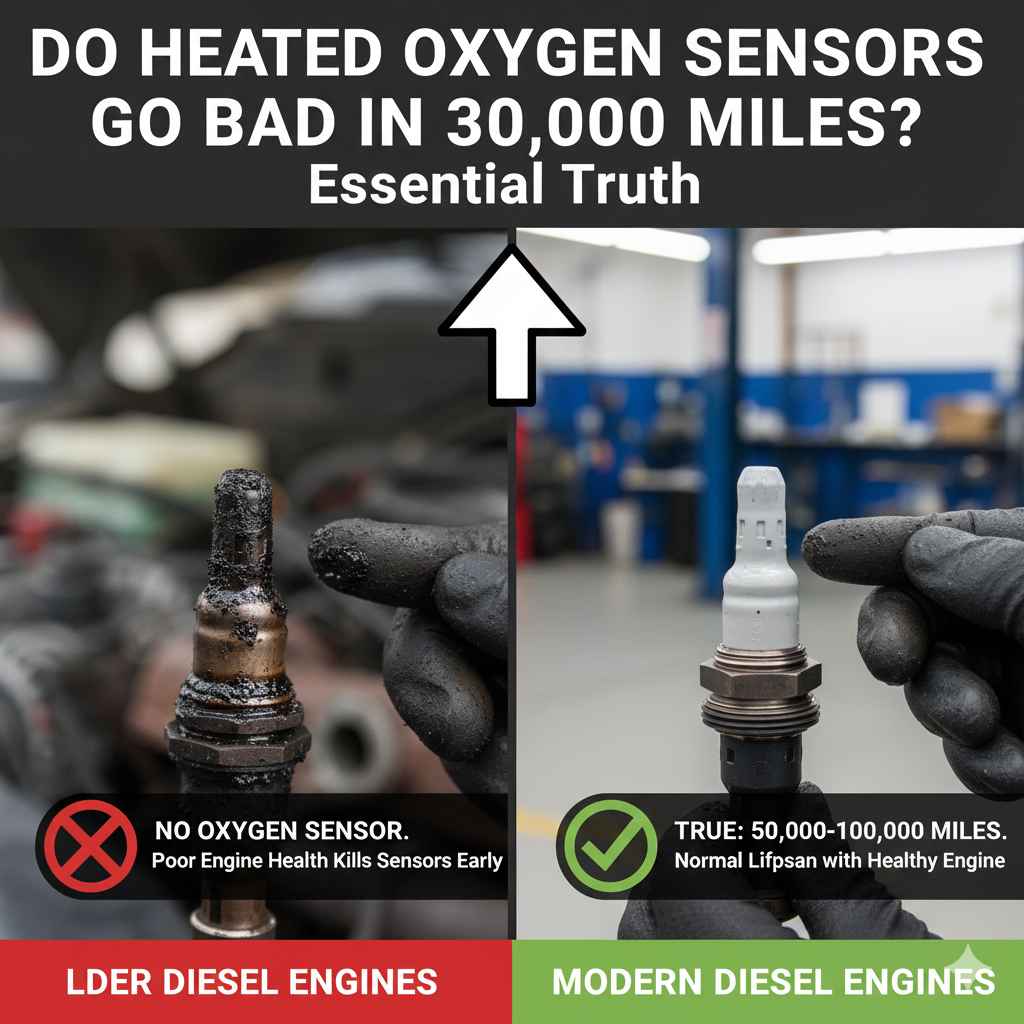

The short answer? It is unusual, but definitely possible. Most high-quality, factory-installed heated oxygen sensors are rated to last well past 100,000 miles under ideal conditions. If your car is only at 30,000 miles, it suggests something other than simple “wear and tear” is causing the issue.

Normal vs. Premature Failure

Let’s look at what “normal” looks like versus what might be happening around 30k miles:

| Condition | Expected Lifespan | Reason for the 30k Issue |

|---|---|---|

| Normal Wear and Tear | 80,000 – 120,000 miles | Sensor ages naturally due to exposure to heat and exhaust gases. |

| Premature Failure (30k Miles) | Often less than 50,000 miles | Usually caused by contamination (oil, coolant) or a failing heater circuit. |

If your vehicle is new, the immediate suspect is not the sensor itself, but what is flowing into it through the exhaust stream. A sensor doesn’t just go bad; it usually gets poisoned or damaged.

The Top 5 Reasons Why Your O2 Sensor Died Young

When an O2 sensor fails around 30,000 miles, it almost always points to an underlying problem in the engine or fuel system that has damaged the delicate sensing tip. Here are the most common culprits that shorten an O2 sensor’s life dramatically.

1. Contamination by Coolant or Oil Leaks

This is perhaps the number one killer of new O2 sensors. If your engine is burning oil (perhaps due to worn piston rings) or leaking coolant into the combustion chamber (like a bad head gasket), those contaminants enter the exhaust stream.

These chemicals coat the sensor element. Silicon (from coolant) or lead/phosphorus (from oil additives) essentially “poison” or clog the sensor. Once coated, the sensor can no longer accurately “breathe” the exhaust gas, leading to incorrect readings or outright failure.

2. Unburnt Fuel (Rich Condition)

If your engine runs too rich—using too much fuel for the amount of air—unburnt gasoline blasts through the exhaust. This excess fuel bakes onto the sensor, especially the heater element while cycling on and off. Causes of a rich condition include:

- Failing fuel injectors dripping fuel.

- A faulty Mass Air Flow (MAF) sensor telling the computer the engine is starving for fuel when it’s not.

- A clogged air filter restricting necessary air intake.

3. Heater Circuit Failure

Remember the critical heating element we discussed? This is often where a 30,000-mile failure occurs. The heater circuit gets its power from the car’s electrical system. If the wiring insulation breaks down, or if there’s a short, the heater can burn out. If the heater fails, the sensor will report an error code almost immediately because it cannot reach its operating temperature quickly enough.

4. Poor Quality or Knock-Off Sensors

If an O2 sensor was replaced recently (even if it was just a few months ago) and it’s already failing, the brand matters immensely. Cheap, aftermarket sensors often use lower-grade materials that cannot withstand the high temperatures and chemical environment of your exhaust system.

Always look for OEM (Original Equipment Manufacturer) parts or trusted, high-reputation brands when buying sensors. Quality parts are built to last the full lifespan expected by the vehicle manufacturer.

5. Voltage Spikes or Electrical Issues

The ECU sends a specific voltage signal to the heater circuit. If your car has underlying electrical problems—like an alternator overcharging or intermittent voltage drops—this instability can stress the delicate internal wiring of the sensor, leading to premature burnout.

How to Confirm Your O2 Sensor is Actually the Problem

Before you spend money replacing a sensor, you need to confirm it’s the actual fault. The Check Engine Light (CEL) is generic; it only tells you something is wrong in the emissions or performance system, not specifically what.

Step 1: Reading the Trouble Codes (The Essential First Step)

You need an OBD-II code reader. Basic readers are inexpensive and plug right into the port under your dash. You might get codes like:

- P0133:

- O2 Sensor Circuit Slow Response (Bank 1, Sensor 1)

- P0141:

- O2 Sensor Heater Circuit Malfunction (Bank X, Sensor Y)

The code P0141 points specifically to the heater circuit, which aligns perfectly with a potential early failure point.

Step 2: Visual Inspection for Immediate Clues

If you are comfortable looking under the car (safely, with it cool and jacked up properly), look at the sensor itself. Does the connector look brittle? Is the wiring harness chewed on by rodents? Is the sensor housing heavily coated in black soot, suggesting a rich fuel condition?

Step 3: Monitoring Live Data Streams

This step usually requires a more advanced scan tool, but it’s the best confirmation. You watch the sensor’s voltage readings change while the engine runs.

A healthy sensor voltage should rapidly cycle between high (rich) and low (lean) values, usually several times per second, once fully warmed up. If the voltage stays pegged at 0.1V, or stuck at 0.9V, the sensor is likely lazy or dead.

For a beginner, relying on the specific failure code (like P0141) or consulting a trusted mechanic for a live data check is the safest route.

Troubleshooting: Fixing the Root Cause Before Replacing the Sensor

If you have low mileage (30,000 miles) and a failed sensor, simply swapping the sensor without fixing the underlying leak or fuel problem means the new sensor will likely fail quickly too. This is where maintenance crosses into smart repair.

Actionable Troubleshooting Steps

- Check for Oil/Coolant Consumption: Regularly check your oil and coolant levels between oil changes. If you are topping them off frequently, you have an internal leak that must be addressed first.

- Test Fuel Pressure and Injectors: A mechanic can test the system pressure. If pressure is too high, injectors may stick open, causing the rich condition that kills the sensor.

- Inspect the Air Filter and MAF: Make sure the air path is clear. Clean your MAF sensor gently with specialized cleaner or replace the air filter if it’s extremely dirty.

- Verify Electrical Integrity: Ask a technician to check the voltage supply to the O2 sensor connector. Ensure the wiring harness is intact and free from damage or corrosion, checking the official wiring diagrams for your specific vehicle model.

Failing to address the root cause turns an O2 sensor replacement into a recurring expense, which is definitely not what we want for your wallet or your safety.

The Replacement Process: A Beginner’s Guide to Swapping the Sensor

While diagnostics should always come first, knowing how to replace the sensor is useful. This process often requires specialized tools due to proximity to grime and rust.

Tools You Will Likely Need

- New, high-quality Heated O2 Sensor (ensure it matches the position—Bank 1 Sensor 1, for example).

- Oxygen Sensor Socket or Wrench (often slotted to allow the sensor wire to pass through).

- Ratchet or Torque Wrench.

- Penetrating oil (like PB Blaster).

- Safety glasses and gloves.

Step-by-Step Tool Usage Guide (Safety First!)

Safety Note: Always let the exhaust system cool down completely before working on it. Wear safety glasses.

- Disconnect the Battery: For safety, disconnect the negative battery terminal.

- Locate the Sensor: Identify which sensor failed (Upstream/Before the Cat, or Downstream/After the Cat). The upstream sensor (Sensor 1) generally controls the air/fuel ratio most actively.

- Prep the Sensor: Spray the old sensor threads liberally with penetrating oil. Let it soak for 15–20 minutes. This prevents shearing the threads off the exhaust pipe.

- Remove the Electrical Connector: Unplug the small electrical connection leading from the sensor up toward the engine bay. Follow the wire path carefully.

- Unscrew the Old Sensor: Fit your O2 sensor socket (usually 22mm or 27mm, but check your car first) over the sensor. Use firm, steady pressure with your ratchet to turn counter-clockwise. If it’s very tight, apply more penetrating oil and wait longer.

- Prepare the New Sensor: New sensors often come with anti-seize compound pre-applied to the threads, or a separate packet is included. Apply a thin layer to the threads of the new sensor. Do not get any anti-seize compound on the sensing tip itself.**

- Install the New Sensor: Thread the new sensor in by hand first to ensure you don’t cross-thread. Once finger-tight, use your torque wrench to tighten it to the manufacturer’s specification. This is important for a proper seal.

- Reconnect and Test: Plug the electrical connector back in securely. Reconnect the battery. Start the car and clear the previous trouble codes using your OBD-II scanner. Monitor the live data or drive cycles until the CEL reappears or stays off.

If you see an immediate code for the new sensor, you might have a wiring issue between the sensor plug and the ECU that needs professional attention.

Understanding Sensor Types and Lifespan Differences

Not all O2 sensors are the same, and this affects their expected durability. Modern cars primarily use Zirconia sensors, which are internally heated. Older cars might have unregulated (unheated) sensors, which are slower and wear out differently.

Wideband vs. Narrowband Sensors

Most modern vehicles (especially post-2000) use Wideband sensors upstream (before the converter) because they offer precise, linear readings crucial for direct fuel control. Narrowband sensors are typically used downstream for checking catalytic converter efficiency.

Wideband sensors are more complex, rely heavily on that quick-heating element, and are often more sensitive to contamination, making them slightly more prone to premature failure if contamination exists.

Summary of Lifespan Expectations

| Sensor Type | Typical Location | Expected Life (Miles) | Susceptibility to 30k Failure |

|---|---|---|---|

| Heated Zirconia (Wideband) | Upstream (Pre-Cat) | 80,000+ | High, due to reliance on heater and precision. |

| Heated Zirconia (Narrowband) | Downstream (Post-Cat) | 100,000+ | Moderate; checks efficiency, less active control. |

| Unheated (Older Vehicles) | Anywhere | 50,000 – 80,000 | Lower, but slower to react when cold. |

The Impact of Sensor Failure on Performance and the Law

A failed O2 sensor at 30,000 miles isn’t just an annoying light; it impacts your wallet immediately and could impact your future inspections.

Fuel Economy Plummets

If the upstream sensor fails and defaults to a “safe” rich setting, the ECU adds extra fuel just to be safe. This can cause a noticeable drop in gas mileage—sometimes 10% to 20% worse than normal. For a low-mileage car, this extra fuel burn adds up quickly.

Catalytic Converter Risk

A dead sensor causes the engine to run excessively rich or lean. Running too rich pumps unburnt fuel into the catalytic converter. The converter is designed to burn off fuel, but too much input causes it to overheat, melt internally, and fail. Replacing a catalytic converter is far more expensive than replacing an O2 sensor.

Emissions Testing

In states that require regular emissions testing, a solid Check Engine Light will cause an automatic failure, as the ECU registers that the emissions control system is compromised.

Frequently Asked Questions (FAQs) for Beginner Owners

Q1: Can I safely drive with a bad heated O2 sensor for a while?

A: You can often drive short distances, but it is not recommended long-term. The immediate risk is poor gas mileage and potential damage to your expensive catalytic converter. If the sensor is reporting a heater circuit failure (like code P0141), the car will likely run rich, wasting fuel.

Q2: How much should it cost to replace a heated O2 sensor at 30k miles?

A: Parts alone for a quality sensor can range from $60 to $150, depending on the vehicle. Labor usually takes between 0.5 to 1.5 hours. Total professional replacement often falls between $200 and $450, but this varies wildly by shop rate and sensor location (upstream is often harder to access than downstream).

Q3: Does using premium (high-octane) fuel help O2 sensors last longer?

A: Using the octane rating recommended by your owner’s manual is crucial. If your car requires Regular (87 octane) and you use Premium (93 octane), it won’t hurt the O2 sensor. However, if your car requires Premium and you use Regular, low-octane fuel can cause engine knock, damaging components and potentially leading to burning oil/coolant, which harms the sensor.