Do Exhaust Manifolds Really Kill Horsepower: Proven Essential

Yes, restrictive exhaust manifolds can significantly reduce your car’s horsepower. Upgrading to a less restrictive manifold allows your engine to breathe more freely, improving performance. This guide explains why and how it works, making it essential for maximizing your vehicle’s power.

Ever wondered if that bumpy bit of metal under your hood is quietly stealing your car’s fun? We’re talking about the exhaust manifold. Many car owners feel a bit lost when it comes to what the exhaust manifold does and if it truly impacts their vehicle’s power. It’s easy to feel overwhelmed, but understanding this part is key to unlocking your engine’s full potential. This guide will break down exactly how exhaust manifolds affect horsepower, why they matter, and what you can do about it, all in simple terms. Get ready to learn how to make your car breathe easier and perform better!

The Heart of the Matter: What is an Exhaust Manifold?

Think of your car’s engine as a powerful beast that needs to exhale just as much as it inhales. The exhaust manifold is that crucial first step in letting the engine exhale. It’s attached directly to the engine’s cylinder heads, where your engine burns fuel. Each cylinder in your engine produces exhaust gasses when it does its job.

The exhaust manifold collects these hot, burnt gasses from each cylinder and merges them into a single pipe. This single pipe then connects to the rest of your exhaust system, which carries the gasses away from the car. It’s a vital component that helps your engine run smoothly and efficiently by managing these hot gasses.

Why the Design Matters for Performance

The way an exhaust manifold is designed is more important than many people realize. Early or standard manifolds are often built with cost and ease of manufacturing in mind. This usually means they are made from cast iron, which is durable but heavy and can sometimes have rough internal surfaces and tight bends. These characteristics can restrict the flow of exhaust gasses.

Imagine trying to rush out of a crowded room through a narrow doorway with a lot of obstacles. It would be slow and difficult, right? That’s what happens inside a restrictive exhaust manifold. The engine has to push harder to force the exhaust gasses out, and this extra effort costs energy. When energy is lost, so is horsepower.

Do Exhaust Manifolds Really Kill Horsepower? The Science Explained

Yes, absolutely. Restrictive exhaust manifolds can indeed steal horsepower from your engine. This happens primarily due to something called “backpressure.”

Understanding Backpressure

Backpressure is the resistance the exhaust gasses encounter as they try to exit your engine. A well-designed exhaust system aims to manage backpressure, not eliminate it entirely, but an overly restrictive manifold creates excessive backpressure.

When the manifold’s design, internal shape, or condition hinders the free flow of exhaust, the gasses can’t escape quickly enough. This causes them to pile up, creating pressure that pushes back against the upward movement of the pistons in the engine. Each piston has to fight against this built-up pressure, which takes away from the power that could otherwise be used to turn the wheels.

The Impact on Engine Breathing

Your engine needs to “breathe” efficiently – that means taking in a fresh charge of air and fuel, and then expelling the waste gasses completely and quickly. A restrictive exhaust manifold acts like a clogged throat for your engine.

When the engine can’t exhale efficiently, it’s harder for it to take in a new, clean charge of air and fuel for the next combustion cycle. Think about it: if you’re holding your breath, it’s hard to take a deep, fresh inhale. The same principle applies to your engine. This poor “breathing” ability directly leads to reduced power output.

Horsepower Loss: How Much Are We Talking About?

The amount of horsepower lost can vary significantly. A standard, cast-iron manifold on a typical passenger car might rob anywhere from 5 to 15 horsepower compared to a well-designed performance manifold, sometimes even more on highly tuned engines. For most everyday drivers, this might not be dramatically noticeable. However, for performance enthusiasts or those looking to optimize their vehicle, even small losses add up.

It’s not just about peak horsepower either. A restrictive manifold can also affect your engine’s torque curve, making acceleration feel sluggish, especially at lower RPMs when exhaust flow is less consistent.

When Exhaust Manifolds Go Bad: Signs of Trouble

While a factory manifold might just be less efficient, they can also develop problems that directly impact performance and even safety. Keeping an eye out for these signs can help you catch issues before they become major headaches.

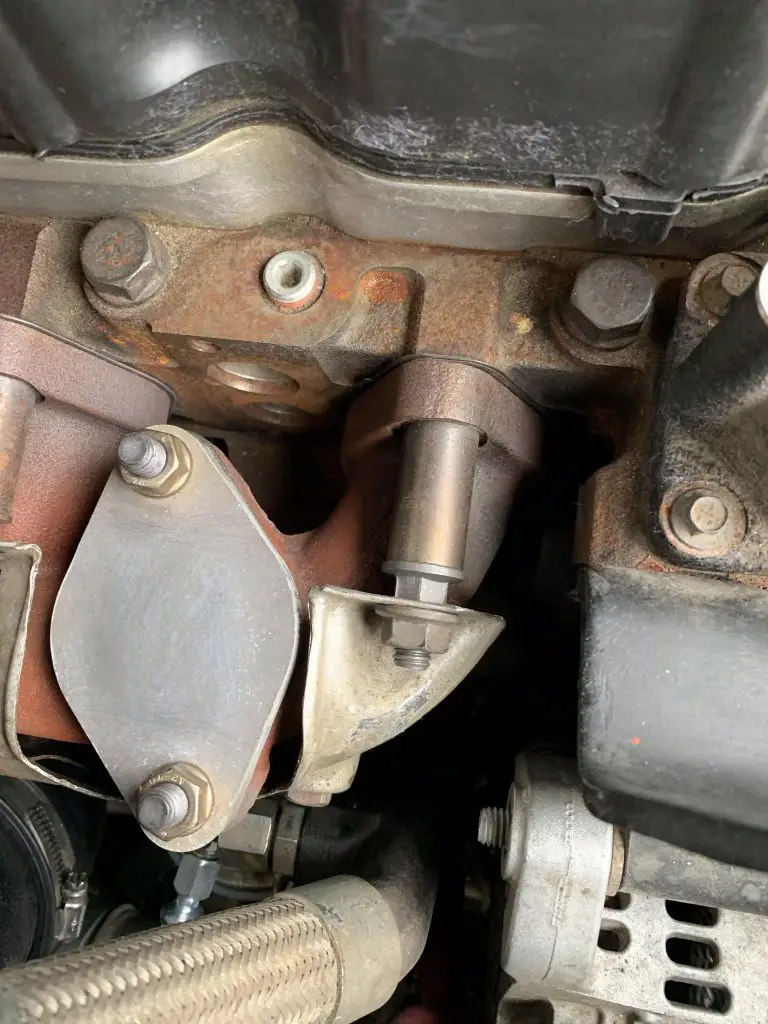

Cracks and Leaks

Exhaust manifolds are subjected to extreme heat cycles and vibrations. Over time, cast iron can develop cracks. These cracks are problematic for a few reasons:

- Exhaust Leaks: A cracked manifold will leak exhaust gasses before they enter the rest of the exhaust system. This can create a ticking or puffing sound, especially when the engine is cold.

- Performance Drop: Leaks cause a loss of exhaust gas velocity, which can negatively affect engine scavenging (the process of pulling exhaust gasses out). This leads to reduced power.

- Smell: Leaked exhaust fumes under the hood can enter the vehicle’s cabin, posing a health risk due to carbon monoxide. For more information on exhaust system safety, the Environmental Protection Agency (EPA) provides valuable safety data regarding vehicle emissions.

- Reduced Efficiency: If the exhaust isn’t flowing correctly, your engine management system might try to compensate, leading to less efficient fuel consumption.

Warping

Extreme heat can cause the manifold to warp, meaning it loses its flat mating surface against the cylinder head. When this happens, it’s almost impossible to get a good seal, leading to persistent exhaust leaks.

Corrosion

In areas with road salt or high humidity, exhaust manifolds, especially those made of cast iron, can rust and corrode. While not always a direct horsepower killer, severe corrosion can weaken the metal and eventually lead to cracks or make it difficult to remove and reinstall the manifold without damage.

Types of Exhaust Manifolds and How They Affect Horsepower

Not all exhaust manifolds are created equal. Their design directly influences how well they manage exhaust gas flow and, therefore, horsepower.

1. Factory (Cast Iron) Manifolds

These are the standard manifolds that come on most production cars. They are typically made from heavy, durable cast iron. While robust, their design often prioritizes cost and packaging within the engine bay over optimal exhaust flow. They tend to have smaller, more restrictive internal passages and less ideal runners (the pipes that lead from the cylinders) to save space.

- Pros: Durable, inexpensive to manufacture, good at insulating heat.

- Cons: Restrictive, heavy, can crack, not designed for performance.

- Horsepower Impact: Can significantly hinder performance by creating backpressure.

2. Tubular or Equal-Length Headers

These are performance-oriented manifolds, often called “headers.” They are usually made from bent steel tubing. The key advantage is their design, which allows for:

- Smoother Flow: The bent tubing provides smoother, less turbulent pathways for exhaust gasses.

- Equal Runner Lengths: Each cylinder’s exhaust pulses travel roughly the same distance before merging. This “scavenging” effect helps pull exhaust out of the previous cylinder’s port, improving volumetric efficiency (how well the engine fills and empties its cylinders).

- Optimized Diameter: The diameter of the tubes is carefully calculated for the engine’s displacement and intended RPM range to balance flow and scavenging.

The efficiency of exhaust pulse scavenging is a well-researched area in automotive engineering. For a deeper dive into the principles of exhaust tuning and scavenging, resources like those found in university engineering departments often provide extensive technical documentation detailing fluid dynamics and engine performance relationships. For instance, the principles of ‘wave tuning’ in exhaust systems are a critical factor that optimized headers leverage.

For example, a common design is a 4-1 header, where the four exhaust runners from the engine merge into one collector pipe. Another is a 4-2-1 header, which uses intermediate collectors for better scavenging at lower RPMs.

Types of Headers:

- Tri-Y Headers: These typically have runners that collect in pairs, then those pairs collect again before merging into a single pipe. They are often tuned for mid-range torque.

- 1-3/4″ to 2″ Primary Tube Diameter: The diameter of the tube closest to the exhaust port. Smaller diameters are better for low-end torque and naturally aspirated engines, while larger diameters help higher-RPM horsepower on boosted or larger displacement engines.

- Collector Size: The size of the point where all runners merge.

Pros: Significantly improved exhaust flow, reduced backpressure, can increase horsepower and torque, often lighter than cast iron.

Cons: More expensive, can be louder, may not fit easily in all engine bays, can reduce underhood heat insulation, might require other supporting modifications for best results.

Horsepower Impact: Can yield gains of 5-25+ horsepower depending on the engine, application, and supporting modifications.

3. Stainless Steel vs. Mild Steel Headers

Headers are often made from either mild steel or stainless steel. Stainless steel is more expensive but offers superior corrosion resistance and durability, making it a better long-term investment, especially in harsher climates.

Material Comparison Table

| Feature | Mild Steel Headers | Stainless Steel Headers |

|---|---|---|

| Cost | Lower | Higher |

| Durability | Good, but prone to rust/corrosion | Excellent, highly resistant to rust |

| Lifespan | Shorter, especially in wet/salty conditions | Longer |

| Weight | Generally similar | Generally similar |

| Appearance | Can rust quickly, often coated | Stays shiny longer, can develop surface rust if not maintained |

The Horsepower Gains: What to Expect from an Upgrade

When you upgrade from a restrictive factory manifold to a performance header, you’re essentially giving your engine a better way to breathe out. This leads to several performance improvements:

Increased Horsepower and Torque

As mentioned, the primary benefit is an increase in both horsepower and torque. Headers improve the engine’s ability to expel exhaust gasses, which allows for a more complete filling of the cylinders with fresh air and fuel mixture. This improved “volumetric efficiency” translates directly into more power. Gains can range from modest to significant, typically seen across the RPM band, but often most pronounced in the mid to upper ranges.

Improved Throttle Response

With less resistance in the exhaust system, the engine can respond more quickly to changes in throttle input. This means when you press the gas pedal, the engine feels more immediate and eager, making the car feel more alive.

Better Fuel Efficiency (Sometimes!)

This might sound counterintuitive, but improved exhaust flow can sometimes lead to better fuel efficiency. When the engine doesn’t have to work as hard to push out exhaust gasses, it can use fuel more efficiently. However, this is highly dependent on driving style. If the extra power means you’re driving more aggressively, you’ll likely use more fuel. The key is that the potential for better efficiency exists.

Engine Sounds

Performance headers can change the sound of your exhaust. They often produce a deeper, more aggressive tone. While many enthusiasts enjoy this, it’s important to be aware that it usually makes the exhaust louder than a stock system. Always check local noise regulations.

Installing an Exhaust Manifold/Header: A Beginner’s Guide

Upgrading your exhaust manifold to headers is a popular modification. While it can be done at home, it requires patience and some basic automotive knowledge. Safety is paramount!

Tools You’ll Likely Need

Gathering the right tools before you start will make the job much smoother. You’ll typically need:

- Socket Wrench Set: With various deep and shallow sockets (metric and standard, depending on your car).

- Wrenches: Combination wrenches.

- Breaker Bar: For stubborn bolts.

- Penetrating Oil: Absolutely essential for loosening rusted bolts. Let it soak!

- Torque Wrench: To tighten bolts to the correct specification.

- Gasket Scraper: To clean old gasket material from engine surfaces.

- Gloves and Safety Glasses: Always protect yourself!

- Floor Jack and Jack Stands: For safely lifting and supporting the vehicle.

- New Exhaust Gaskets: Crucial for a proper seal.

- Optional: New exhaust manifold studs/bolts if the old ones are damaged.

Step-by-Step Installation Process (General)

This is a general guide. Always consult your vehicle’s specific service manual for detailed instructions.

- Safety First: Park your car on a level surface, engage the parking brake, and disconnect the battery. If you need to lift the car, use a proper floor jack and always support it with jack stands. Never work under a car supported only by a jack.

- Access the Manifold: You might need to remove other components to get to the exhaust manifold. This could include heat shields, engine covers, or even parts of the intake system. Take pictures as you go to remember where things belong.

- Disconnect Exhaust: Locate where the factory exhaust manifold connects to the rest of the exhaust system (usually a flange with bolts or a clamp). Unbolt this connection carefully. You might need to spray penetrating oil on these bolts first.

- Remove Old Manifold: Start unbolting the manifold from the cylinder head. These bolts, or studs and nuts, are often seized by rust and heat. Use penetrating oil generously and allow it time to work. A breaker bar can be helpful, but be careful not to snap off bolts!

- Clean Mating Surfaces: Once the old manifold is off, carefully scrape away any old gasket material from the cylinder head surface. It needs to be perfectly clean and flat for the new gasket to seal properly. A razor blade or gasket scraper works well; be gentle not to gouwith the aluminum head.

- Install New Manifold/Headers: Place the new gasket onto the cylinder head. Position the new headers or manifold. Start by hand-tightening all the bolts or nuts to ensure they thread in correctly and don’t cross-thread. This is also a good time to verify all your primary tubes line up with the collector.

- Torque to Spec: Follow a criss-cross or specific tightening pattern as recommended for your engine. Use a torque wrench to tighten all fasteners to the manufacturer’s specified torque. This even pressure is critical for a good seal and prevents warping.

- Reconnect Exhaust: Reattach the rest of the exhaust system to your new manifold/headers. Ensure a good seal here too, using new gaskets if necessary.

- Reassemble Components: Put back any parts you removed in step 2 (heat shields, covers, etc.).

- Final Checks: Reconnect the battery. Start the engine and listen for any abnormal ticking, puffing, or exhaust leaks. Check for fitment issues.

Important Considerations

- Emissions Regulations: Ensure any aftermarket headers comply with your local emissions laws. Some modifications may require specific catalytic converters or render your vehicle illegal for street use in certain areas. It’s worth checking with organizations like the California Air Resources Board (CARB), which sets some of the strictest emissions standards in the US, for guidance on aftermarket parts.

- Engine Management: On some vehicles, particularly newer ones with sophisticated engine control units (ECUs), installing headers might require tuning the ECU to take full advantage of the increased flow and prevent check engine lights.

- Heat Management: Headers can run hotter than cast iron manifolds and might require heat wraps or shields, especially if routed near sensitive components.

- Fitment: Always buy headers specifically designed for your vehicle’s make, model, and engine to ensure proper fitment and clearance.

Frequently Asked Questions (FAQ)

Q1: My car sounds different after installing headers. Is that normal?

A1: Yes, it’s very common. Headers often produce a louder, deeper, and more aggressive exhaust note compared to stock manifolds. The material and design allow exhaust pulses to exit with less restriction, changing the sound. Just ensure there are no actual leaks!