5.7 Hemi Exhaust Manifold Bolt Torque Sequence

There is no definitive answer to this question as there are many variables that can affect the torque values of exhaust manifold bolts, including the type of engine, the year it was manufactured, and the specific model. However, a good starting point for most 5.7 Hemi engines would be to follow the factory-recommended torque sequence and specifications.

If you’re working on a 5.7 Hemi engine, it’s important to know the proper torque sequence for the exhaust manifold bolts. These bolts are critical to the performance of your engine, so it’s important to do them right. Here’s the torque sequence for the 5.7 Hemi exhaust manifold bolts: 1-3-5-7-2-4-6-8.

Make sure to follow this sequence when tightening these bolts, and you’ll be good to go!

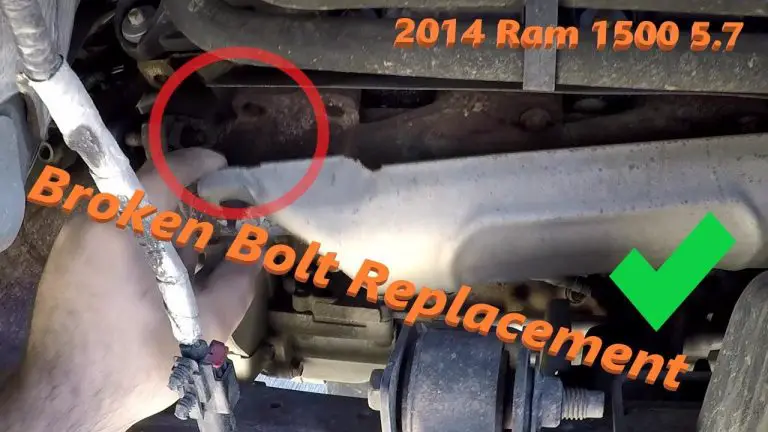

To make this process easier, consider using the 71500 Exhaust Manifold Bolt Stud Drill Template Removal Tool Set for Dodge 5.7L Hemi Motors. This tool is specifically designed to remove broken exhaust manifold bolts without damaging the cylinder head.

5.7 dodge ram Hemi Head bolt torque sequence

2014 5.7 Hemi Head Torque Specs

If you’re working on a 2014 5.7 Hemi engine, you’ll need to know the head torque specs. Here they are:

Stage 1: 55 ft-lbs

Stage 2: 70 ft-lbs

What is the Torque on Exhaust Manifold Bolts?

Torque is the rotational force that an engine produces. It is measured in either Newton meters or foot-pounds, and it indicates how much power an engine can produce. The higher the torque rating, the more powerful the engine.

When it comes to exhaust manifold bolts, the torque rating will usually be between 10 and 15 Newton meters or 7 and 11 foot pounds. This range will vary depending on the size of the bolt and the application for which it is being used. In order to achieve optimal performance from your engine, it is important to use the correct torque when tightening exhaust manifold bolts.

For this, you can use the EPAuto 1/4-Inch Drive Click Torque Wrench. This tool provides the precision required for such tasks and helps prevent over-tightening, which can damage the threads on the bolt.

If you use too little torque, then the bolts may not be properly secured and could come loose over time. This could lead to a dangerous situation where parts of your exhaust system could detach while you are driving. On the other hand, if you use too much torque, then you run the risk of stripping the threads on the bolt or breaking the bolt entirely.

The best way to ensure that you are using the correct amount of torque is to consult your vehicle’s service manual. This will have all of the information that you need in order to properly maintain your vehicle.

Are 5.7 Hemi Head Bolts Torque to Yield?

Is 5.7 Hemi head bolts torque to yield? The answer is no, they are not. The 5.7 Hemi engine actually uses bolts that are stretched to yield.

If you’re looking for replacement bolts, consider the Stage 8 – 8916 MOPAR 4.7, 5.7, 6.1 Liter Hemi V8 Header Bolt Kit. This kit is specifically designed for the 5.7 Hemi engine, ensuring compatibility. It includes 17 pieces of 8mm 1.25x25mm bolts, which are essential for the exhaust manifold bolt torque sequence.

This means that when the bolts are tightened, they are stretched a specific amount and then stopped. This helps ensure that the clamping force is correct and that there isn’t too much or too little tension on the bolt which could lead to problems.

How Do You Torque Exhaust Manifold Studs?

If you’re looking to torque your vehicle’s exhaust manifold studs, there are a few things you’ll need to keep in mind. One of the things you might need is a set of new studs. The Dorman 03405 Exhaust Manifold Hardware Kit is a good option, although it’s designed for select Ford models, so make sure to check the compatibility with your vehicle.

First, it’s important to know that most exhaust manifolds are made of cast iron, which means they’re more brittle and susceptible to breaking than other types of metals. This is why it’s important to be careful when torquing the studs, as too much force can easily break them.

In terms of actually torquing the studs, it’s best to use a torque wrench set to around 15-20 ft/lbs. Once all of the studs have been tightened down, go back and check each one to make sure that they’re all at the same level of tightness. If not, adjust accordingly until they are.

Finally, don’t forget to apply a liberal amount of anti-seize compound onto the threads before reassembling everything – this will help prevent the studs from rusting or seizing up over time.

A good option for this is the Copper Anti Seize Lubricant. This high-temperature grease will ensure the bolts do not seize or get stuck, making it easier for you to follow the torque sequence.

For more insights on the tightening sequence of exhaust manifold bolts, check out this forum thread on the DODGE RAM FORUM.

How Do You Tighten Exhaust Manifold Bolts?

There are a few different ways that you can tighten exhaust manifold bolts, depending on the type of vehicle that you have. If you have a car with an internal combustion engine, the most common way to tighten exhaust manifold bolts is by using a wrench. You will need to use a wrench that fits the size of the bolt head.

Place the wrench on the bolt head and turn it clockwise until it is tight. Another way to tighten exhaust manifold bolts is by using a torque wrench. This method is more accurate than using a regular wrench and will help to prevent over-tightening, which can damage the threads on the bolt.

To use a torque wrench, first, find out what the recommended torque setting is for your vehicle from the owner’s manual or a repair guide. Then, set the torque wrench to this setting and attach it to the bolt head. Turn the wrench clockwise until it clicks, which indicates that it has reached the correct torque setting.

If you are working on an older vehicle, you may need to use an impact gun to loosen and tighten exhaust manifold bolts. An impact gun uses compressed air to generate enough force to loosen or tighten stubborn nuts and bolts. To use an impact gun, first, make sure that there is enough pressure in the air tank.

Credit: mechanics.stackexchange.com

Conclusion

This blog post covers the torque sequence for the 5.7 Hemi exhaust manifold bolts. It is important to follow this sequence when tightening the bolts, in order to avoid damaging the engine. The first step is to tighten the bolts that connect the manifold to the cylinder head.

Next, you will tighten the bolts that attach the manifold to the catalytic converter. Finally, you will finish by tightening any remaining bolts that secure the manifold in place.