5.9 Cummins Exhaust Manifold Bolt Size

The standard size for the bolts that hold a 5.9 Cummins exhaust manifold in place is 3/8-16. Most hardware stores will have these in stock, and they can also be ordered online or through a Cummins dealer. It is important to use the correct size and type of bolt, as using anything else could result in damage to the engine or exhaust system.

The exhaust manifold on the 5.9 Cummins is held together by bolts that are 3/8″ in diameter. There are 18 of these bolts total, and they should be torqued to between 30 and 40 ft-lbs.

EASY Upgrade For Cummins Exhaust Manifolds That You Don't Think Of | Fleece Exhaust Manifold Studs

5.9 Cummins Exhaust Manifold Bolt Torque

If you’re working on a 5.9 Cummins engine, you’ll need to know the torque specs for the exhaust manifold bolts. Here’s a quick rundown of what you need to know.

The exhaust manifold bolts on a 5.9 Cummins engine should be torqued to 80 ft-lbs.

This is an important specification to remember, as overtightening these bolts can damage the threads in the cylinder head.

When installing or removing the exhaust manifold, it’s also important to use new gaskets. Old gaskets can cause leaks, which will result in decreased performance and increased noise levels from the engine.

6.7 Cummins Exhaust Manifold Bolts

If you’re looking to upgrade the exhaust on your 6.7 Cummins, one of the first places to start is with the exhaust manifold bolts. These bolts are designed to withstand high temperatures and provide a tight seal between the manifold and engine. However, over time they can become loose or even break completely.

This can cause serious damage to your engine, so it’s important to check them regularly and replace them if necessary. Here’s a quick guide on how to do just that:

First, remove the old bolts from the exhaust manifold.

You may need a wrench or socket set to loosen them up. Next, clean off any debris or rust from the surface of the manifold. This will help ensure a tight seal when you install the new bolts.

Now, thread in the new bolts by hand until they’re snug against the manifold. Be careful not to overtighten them – just snug is good enough. Finally, use a wrench or socket set to tighten each bolt until it’s secure.

And that’s it! Just repeat this process every few months or so to keep your 6..7

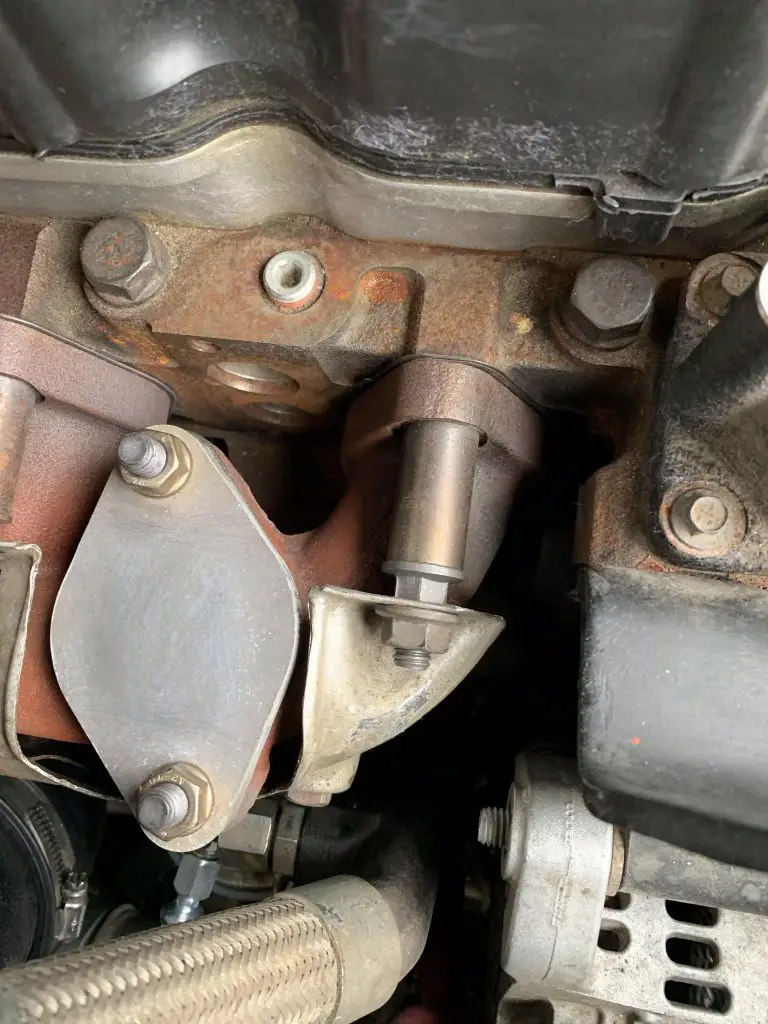

6.7 Cummins Exhaust Manifold Bolt Spacer

If you’re looking to upgrade your 6.7 Cummins exhaust manifold, one of the first things you’ll need is a bolt spacer. In this blog post, we’ll give you a detailed rundown of what a bolt spacer is and how it can benefit your engine.

A bolt spacer is a simple but important piece of hardware that helps to space out the bolts on your exhaust manifold.

This provides two main benefits: first, it prevents the bolts from being too close together and second, it allows for better airflow around the manifold itself. By spacing out the bolts, you’sll also be able to use larger diameter bolts if needed without having clearance issues.

Installing a bolt spacer is relatively easy and can be done in just a few minutes with basic hand tools.

Simply remove the old bolts and spacers (if present) and then install the new spacers in their place. Once installed, simply reinstall the exhaust manifold using the new bolts. That’s all there is to it!

If you’re looking for an easy way to improve airflow and prevent clearance issues on your 6.7 Cummins exhaust manifold, then installing a bolt spacer is definitely worth considering.

6.7 Cummins Exhaust Manifold Warped

If your 6.7 Cummins is experiencing warped exhaust manifolds, don’t despair! Warped exhaust manifolds are a common issue with this engine, but there are a few things you can do to fix the problem.

First, it’s important to understand what causes warped exhaust manifolds in the first place.

The primary culprit is extreme heat. When the engine runs hot, the exhaust manifold expands and contracts, which can cause warping over time. Additionally, improper installation or repairs can contribute to the problem.

If the manifold isn’t installed correctly or if it’s not properly supported, it’s more likely to warp under high temperatures.

There are a few different ways to fix warped exhaust manifolds on a 6.7 Cummins. One option is to replace them with new ones.

This is typically the best option if they’re severely damaged or if you want to avoid future issues. However, replacement manifolds can be expensive, so it’s worth exploring other options first.

If your manifolds aren’t too badly damaged, you may be able to have them machined down so that they’re flush again.

This is usually less expensive than replacing them outright and can often correct the problem just as well. However, it’s important to note that this isn’t a permanent fix; over time, the warping may come back and you’ll need to have them machined again (or replaced).

Credit: www.ecddiesel.com

Should I Use Anti Seize on Exhaust Manifold Bolts?

If you’re asking whether or not you should use anti-seize compound on exhaust manifold bolts, the answer is yes. Applying a small amount of anti-seize to the threads of exhaust manifold bolts will help to prevent them from seizing up over time. It will also make it easier to remove the bolts if they do need to be replaced in the future.

Just be sure not to get any anti-seize on the surfaces of the bolt heads that come into contact with the engine, as this can cause problems down the line.

Should I Use Loctite on Exhaust Manifold Bolts?

It is common practice to use Loctite on exhaust manifold bolts. The main reason for this is to prevent the bolts from loosening over time and causing leaks. Loctite creates a seal between the bolt and the port, which prevents gases from escaping.

It also prevents corrosion, which can cause the bolts to seize.

How Do You Remove Stubborn Exhaust Manifold Bolts?

If you’re trying to remove a stubborn exhaust manifold bolt, there are a few things you can do to make the process easier. First, try using a penetrating oil like WD-40 or Liquid Wrench. Spray the oil onto the bolt and let it sit for a few minutes before trying to loosen it.

You can also try using an impact wrench to loosen the bolt. If you don’t have one, you can try heating up the bolt with a torch. Be careful not to overheat it, though, as this could damage the threads.

Finally, if all else fails, you may need to use a drill and extractor set to remove the bolt.

Is It Common for Exhaust Manifold Bolts to Break?

Yes, it is common for exhaust manifold bolts to break. There are many reasons why this happens, but the most common reason is because the bolts are not properly torqued. When you torque a bolt, you’re essentially tightening it until it reaches a certain level of tightness.

If you don’t torque the bolt correctly, it can become too loose or too tight, and this can cause the bolt to break.

Another reason why exhaust manifold bolts might break is because of corrosion. Over time, rust can build up on the bolts and weaken them.

This is especially common if the vehicle is driven in salt water (like on roads during winter).

If an exhaust manifold bolt breaks, it’s important to replace it as soon as possible. A broken bolt can cause leaks in the exhaust system, which can lead to engine damage or even a fire.

Conclusion

The 5.9 Cummins engine is a workhorse that can be found in many Dodge trucks. When it comes time to replace the exhaust manifold, it is important to use the correct bolt size. The 5.9 Cummins uses a 14mm bolt for the exhaust manifold.